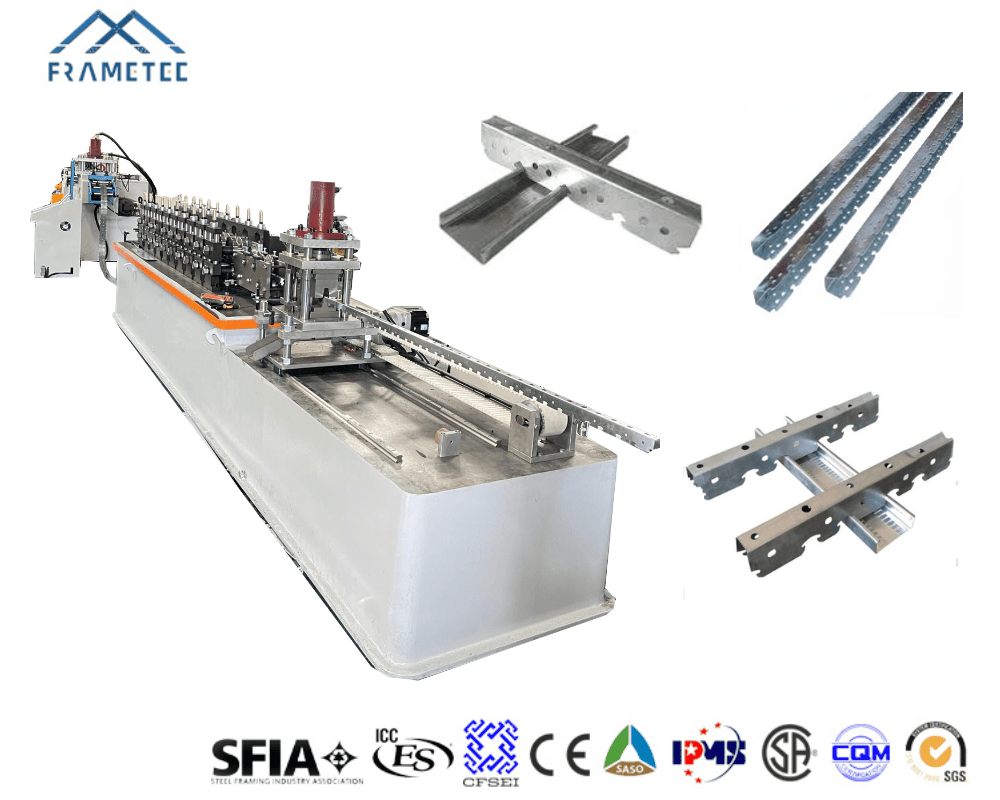

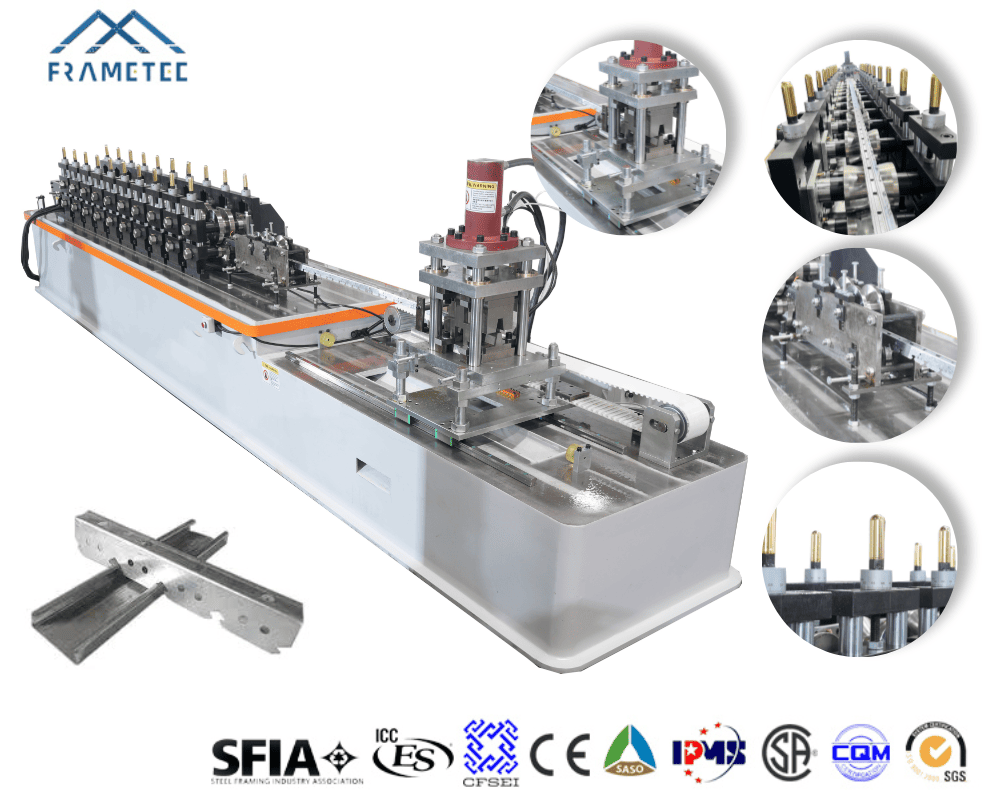

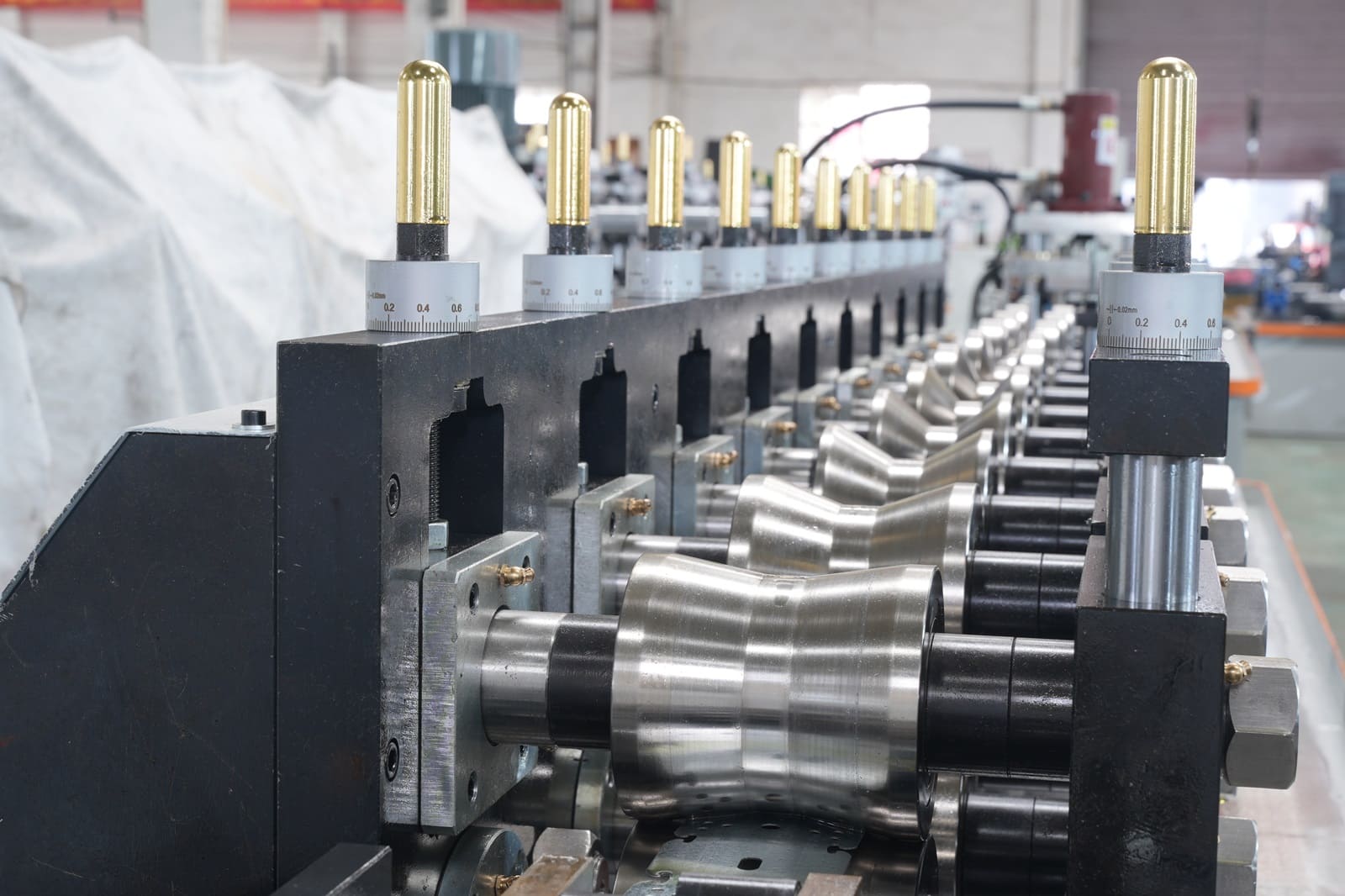

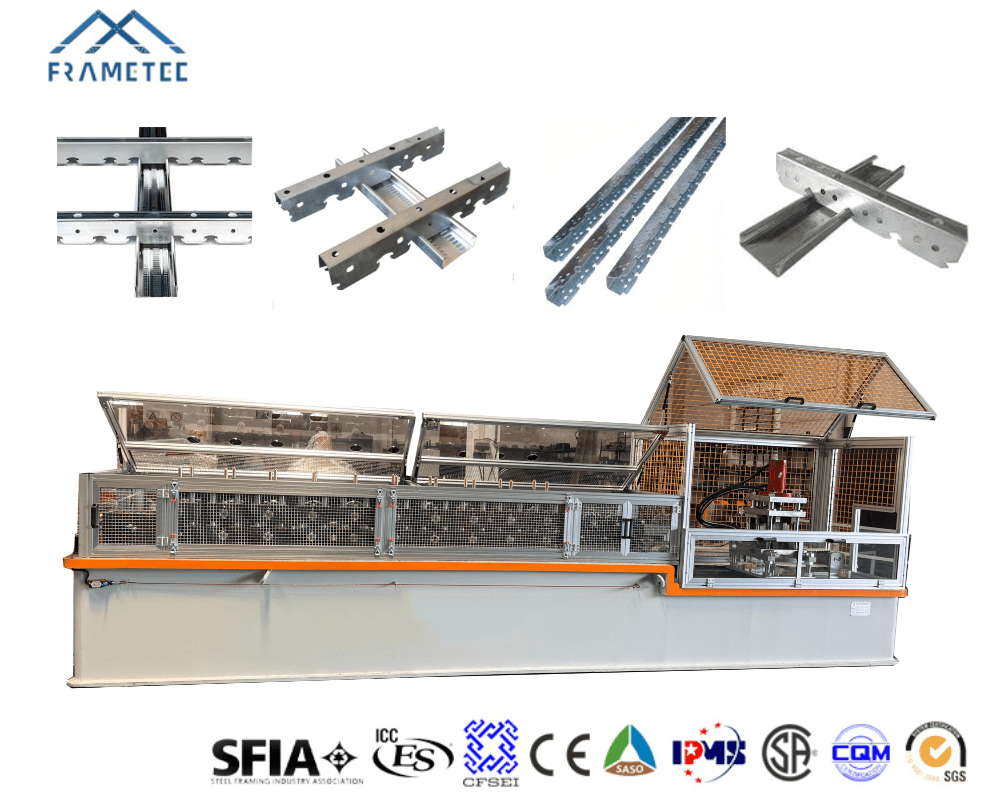

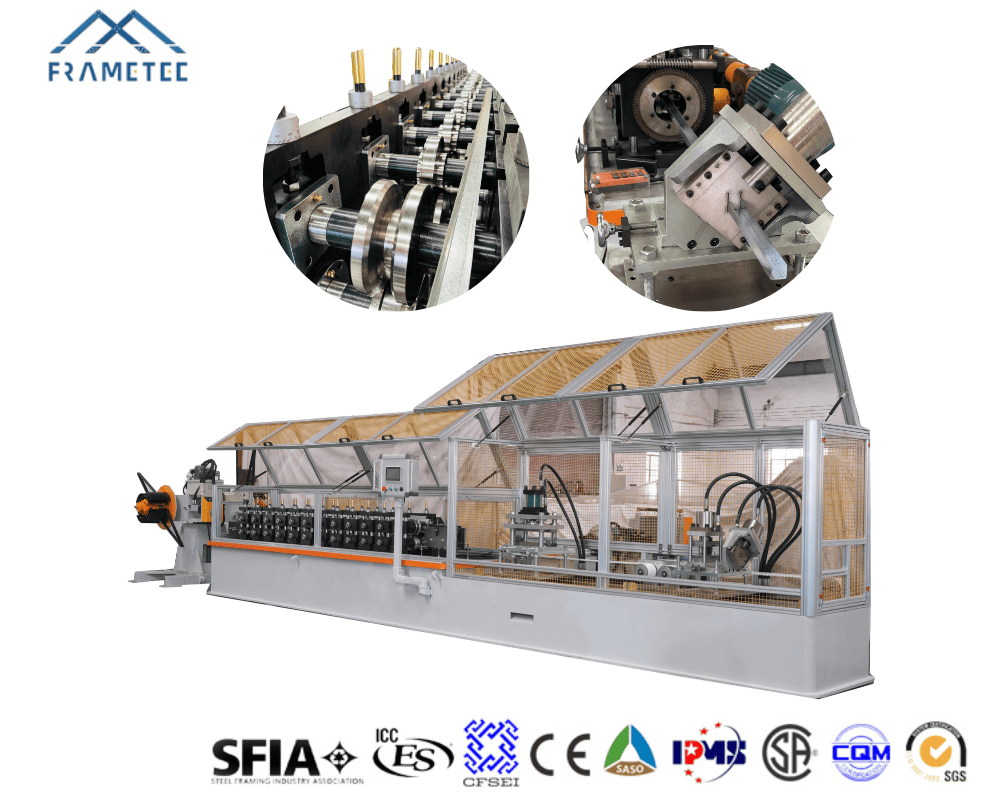

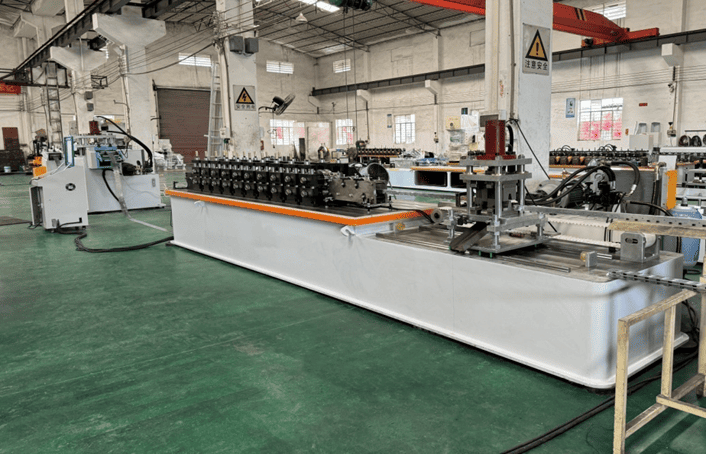

Engineered to European excellence (German scientific design & German/Italian manufacturing standards), the Baffle Channel ROLL FORMER produces high-precision drywall studs and tracks. Its core features imported electrical components and a robust, guided-column frame structure with dial indicators for precise calibration.

Achieve exceptional productivity with variable line speeds from 15 to 80 meters per minute. The integrated high-speed flying shear technology ensures accurate, servo-synchronized punching and cutting. Designed for operational ease, its intuitive controls require no specialist setup, enabling immediate production.

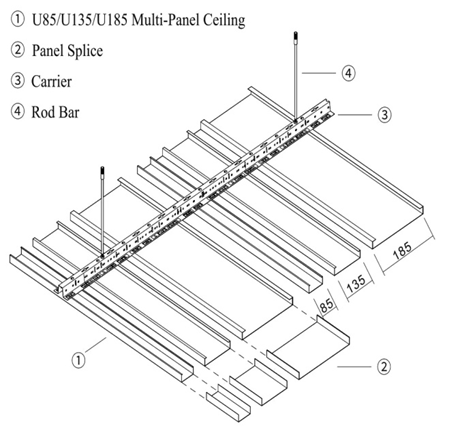

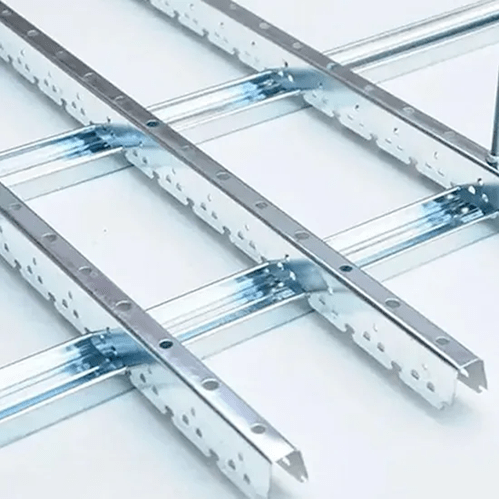

The linear ceiling system consists of metal linear panels that are snapped onto a suspended carrier.Rol-formed steel or pre-painted aluminum strips are used to create linear strip celings. in interior or exterior of big publicspaces like airports, subway stations, train stations, and others, the linear metal ceiling is frequently employed.It offers a square edge design with a linear appearance that improves both the internal and external perspectives ofbuildings.

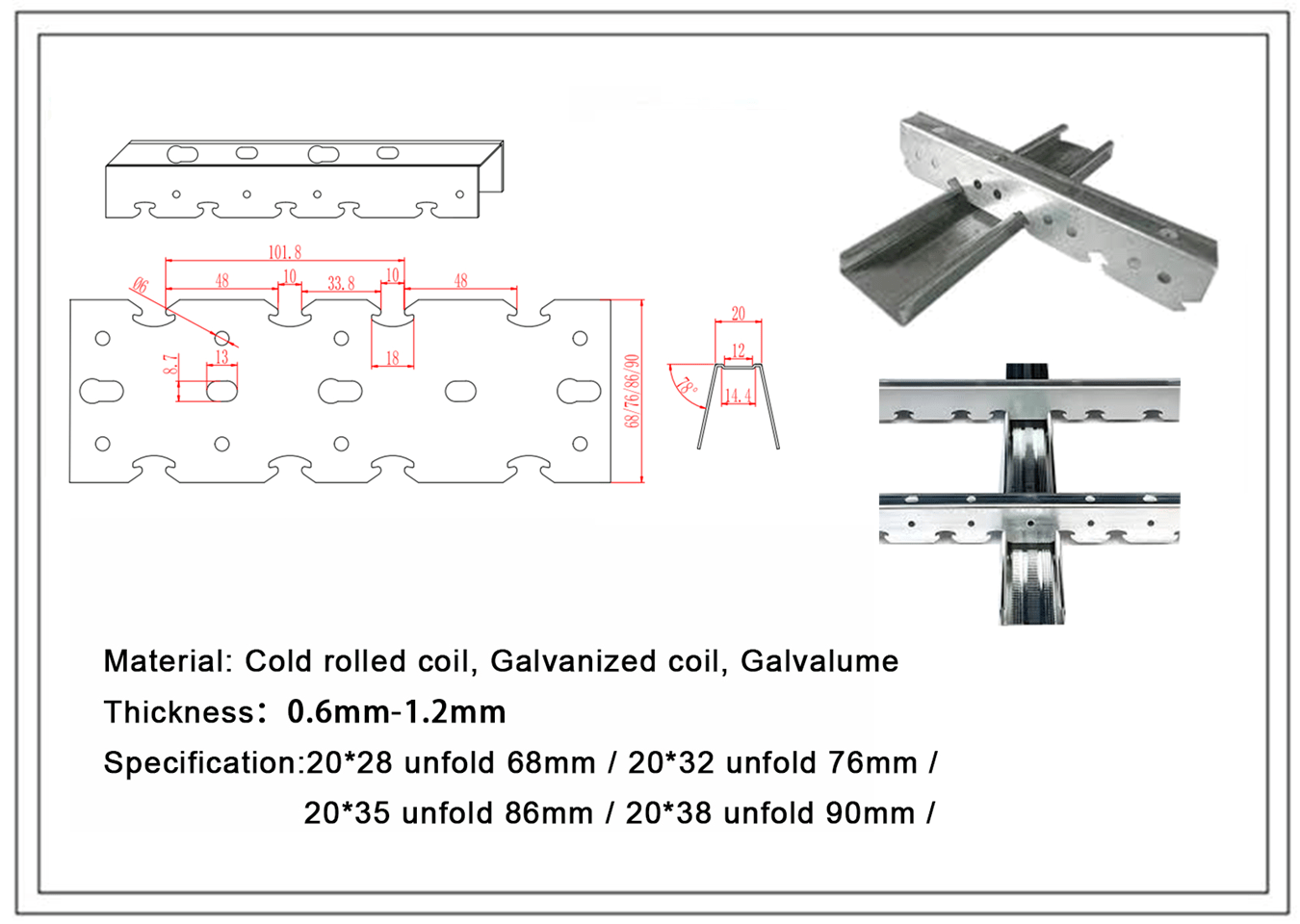

Profile Drawing

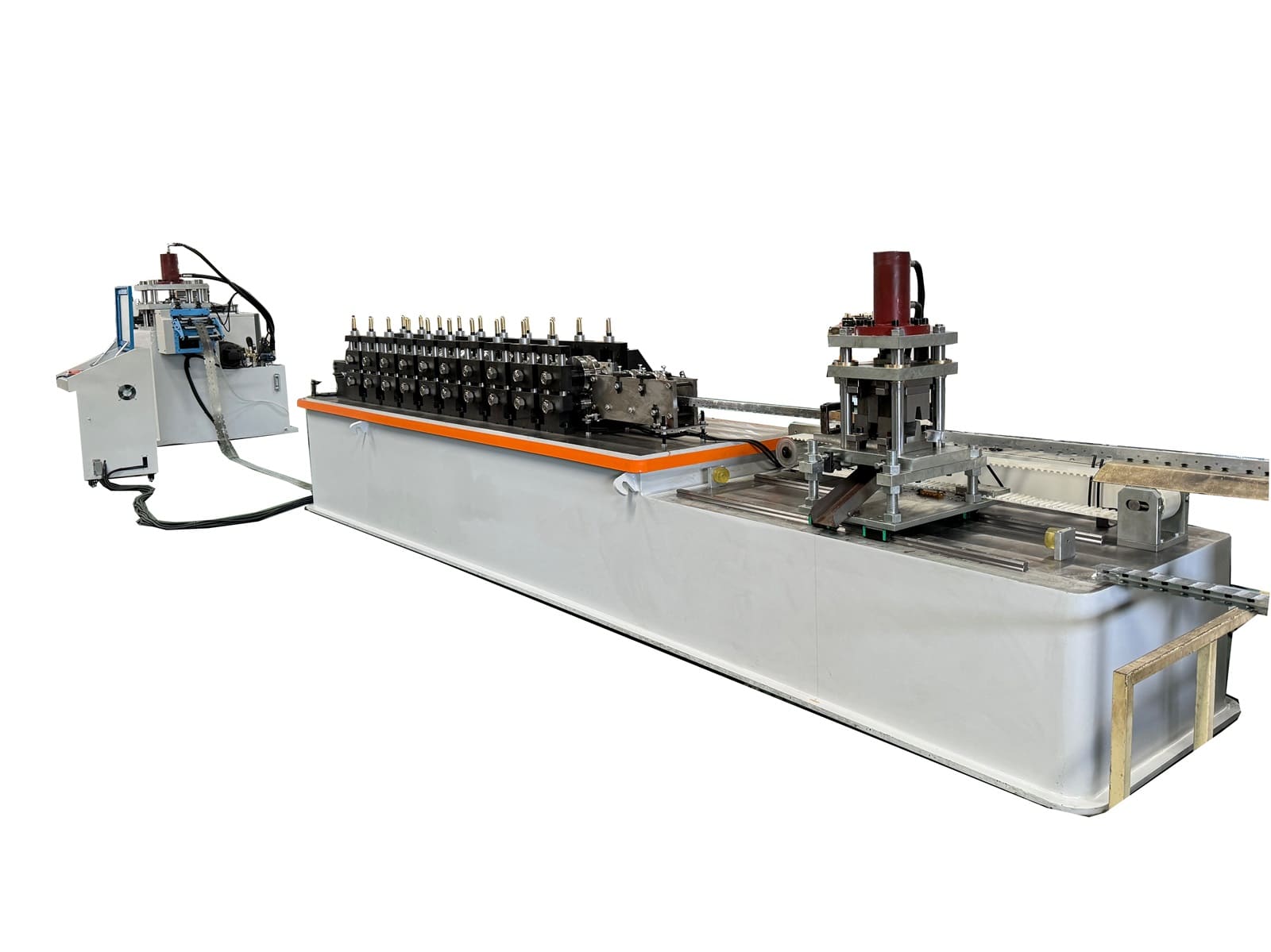

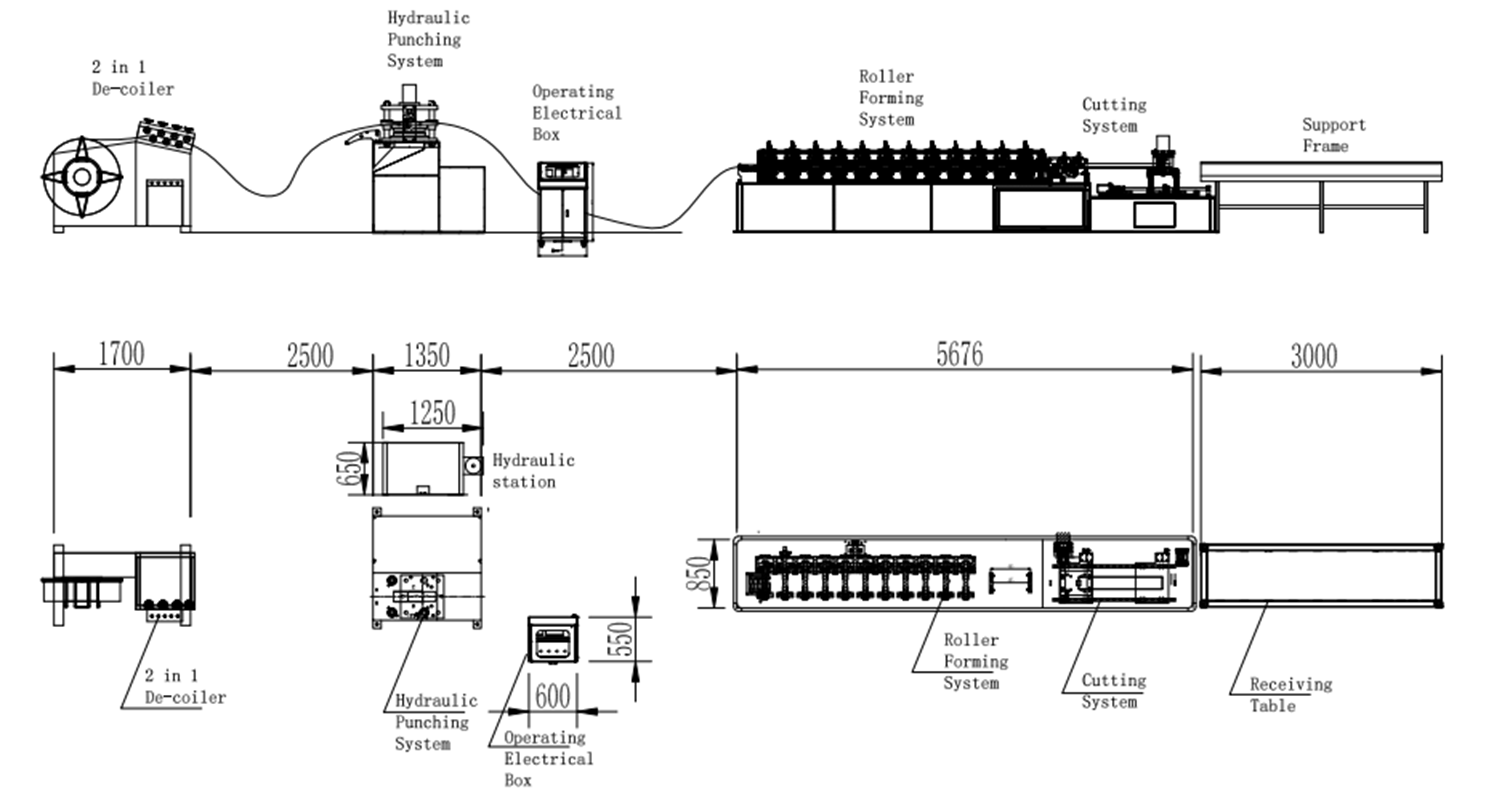

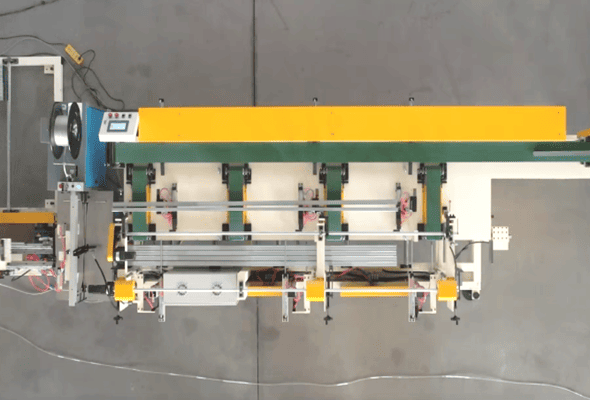

Machine Flow Chart Layout

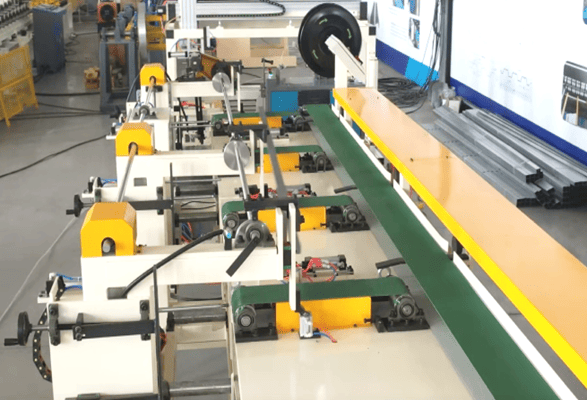

Machine Feature

-Combine the straightener and decoiler

–Hydraulic punch and servo feeder, as well as the primary rolforming machine

-Automatic shearing station

–Support Frame

-Hydraulic and electrical system

The linear strip ceiling carrier also is a solution as the u baffle ceiling if you are a linear ceiling supplier for both types ceiling.this production line is economic choose for you.

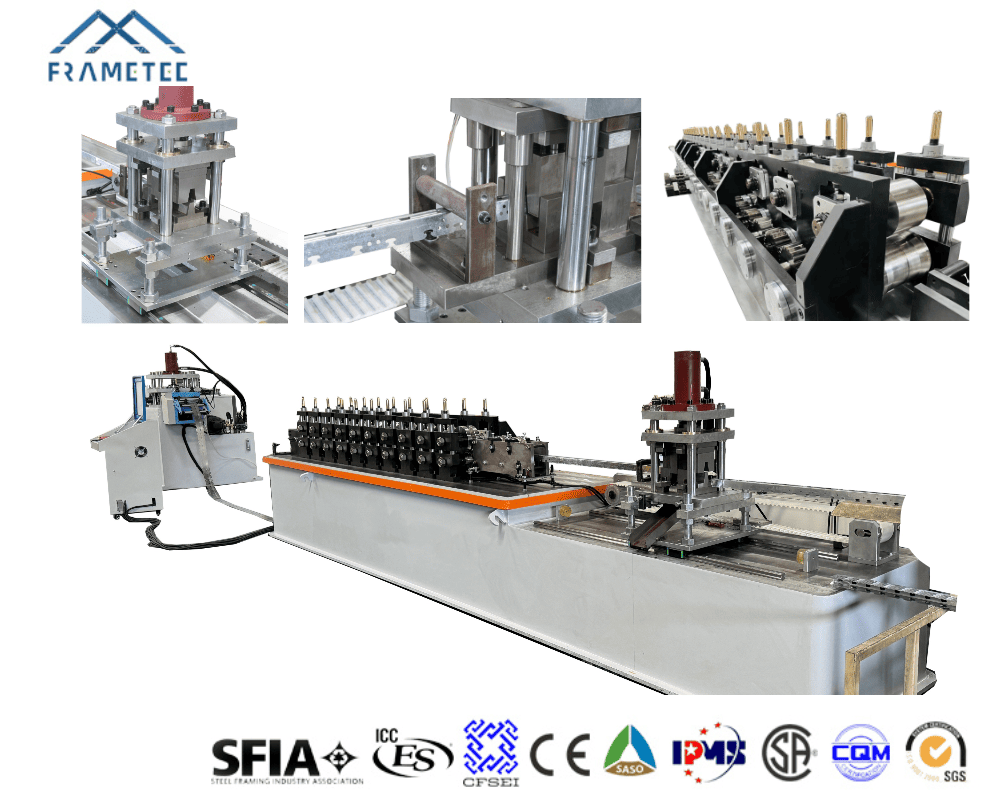

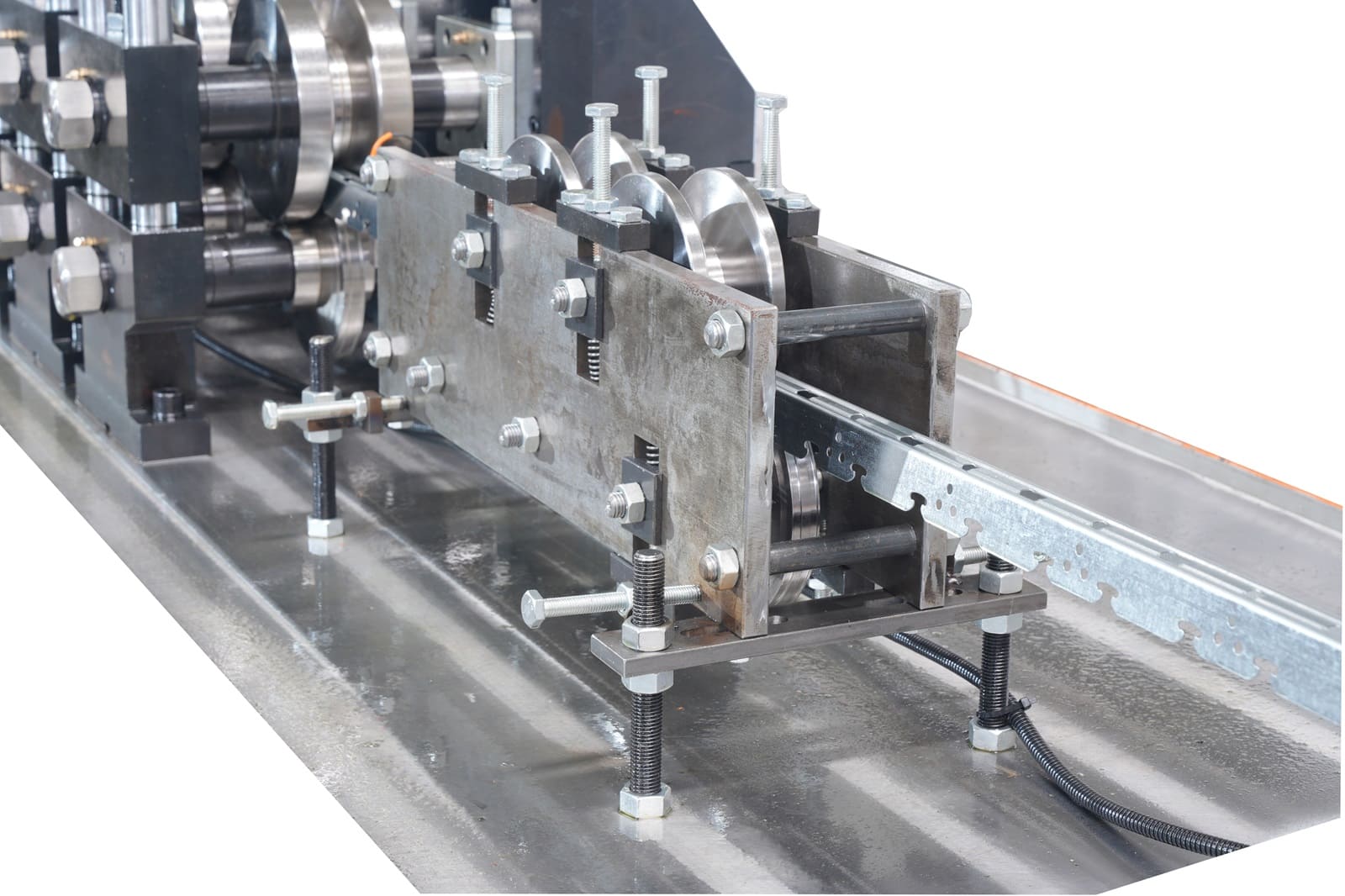

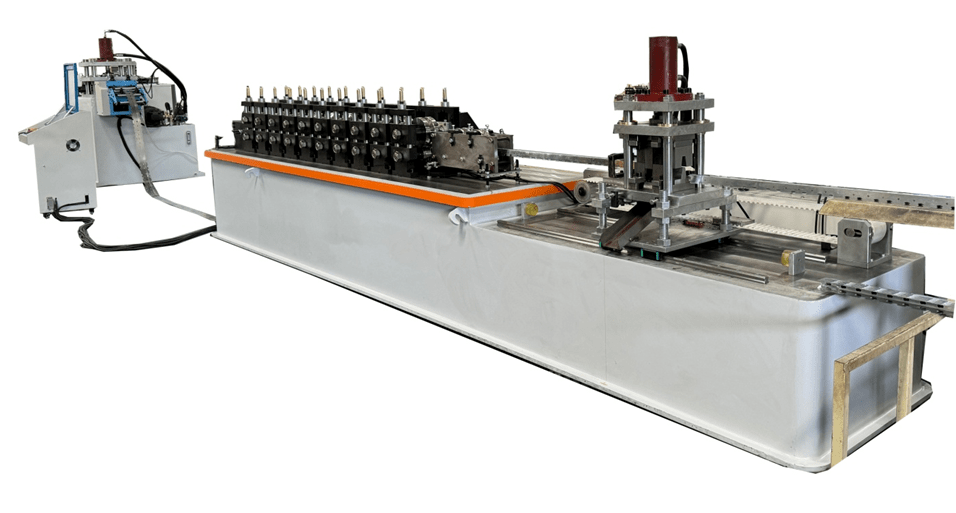

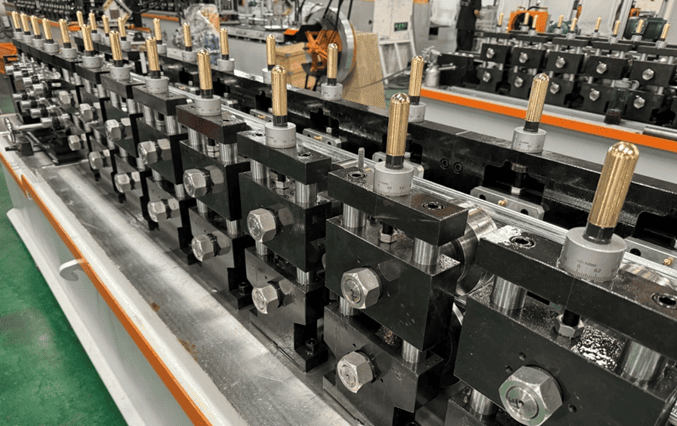

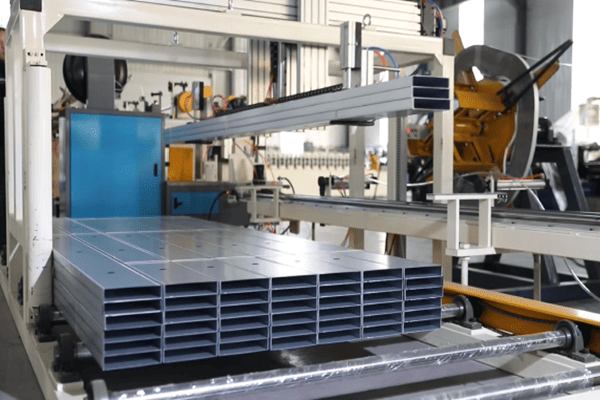

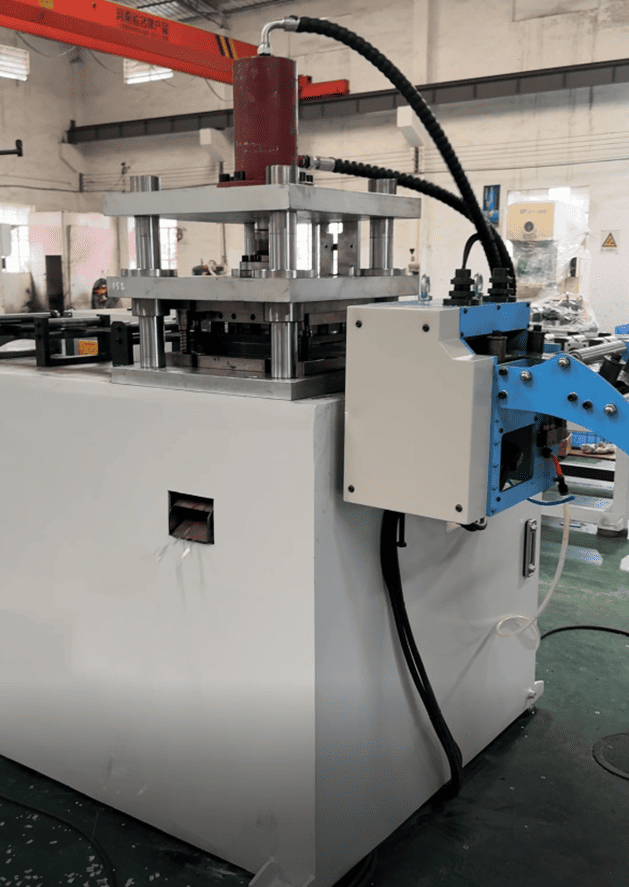

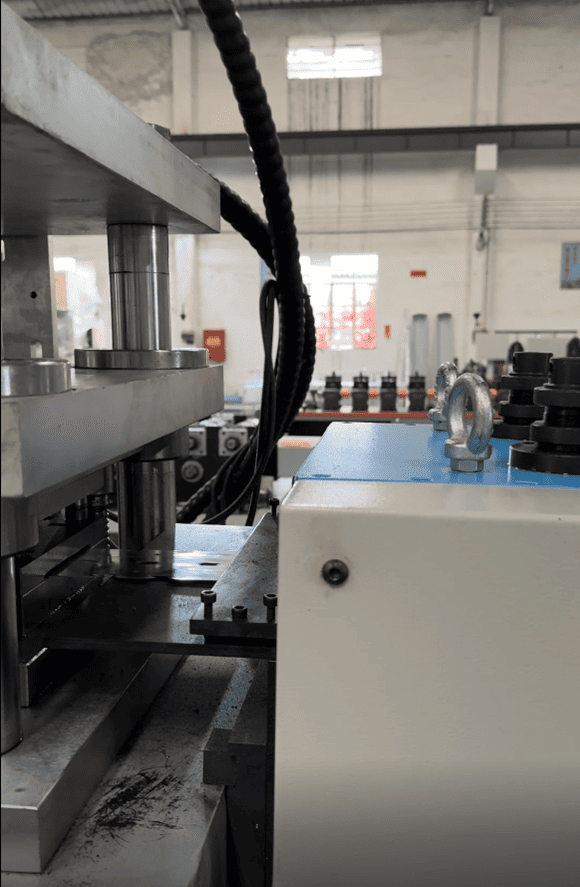

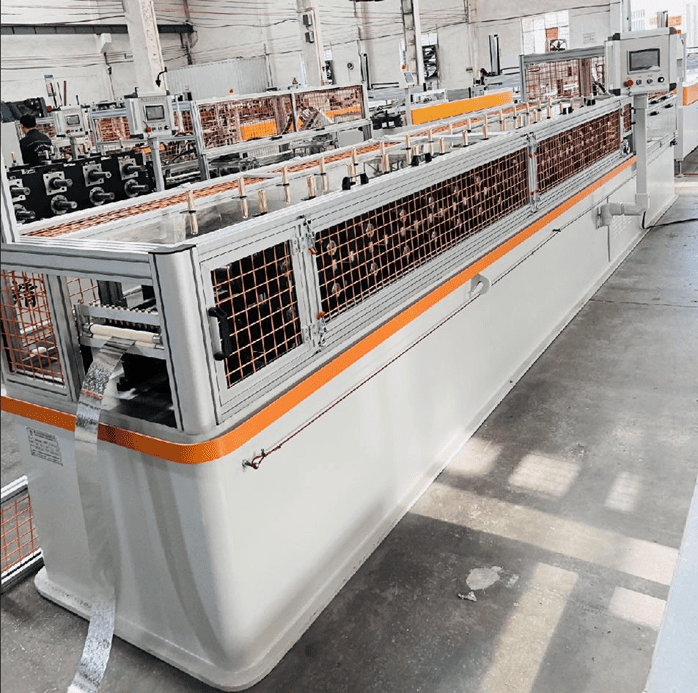

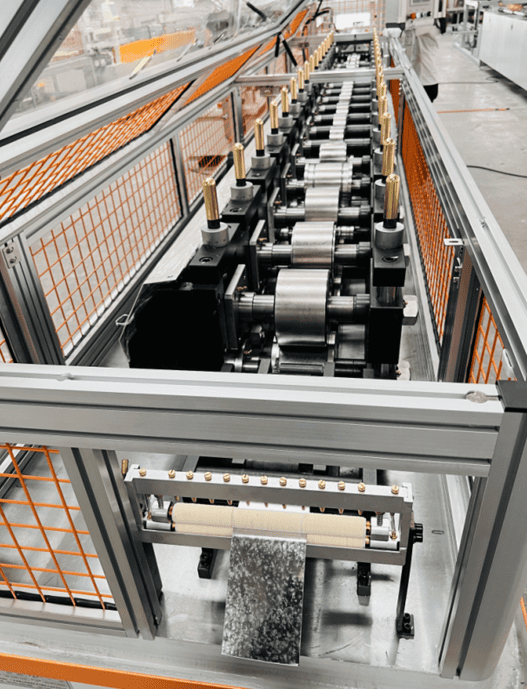

Machine Pictures

| Steel Coil Specs | ||

| Raw Material | Galvanized Steel & H.R |  |

| Material Thickness | 0.6-1.2mm | |

| Yield Strength | 250Mpa-450Mpa | |

| Tensile Strength | 350Mpa-500Mpa | |

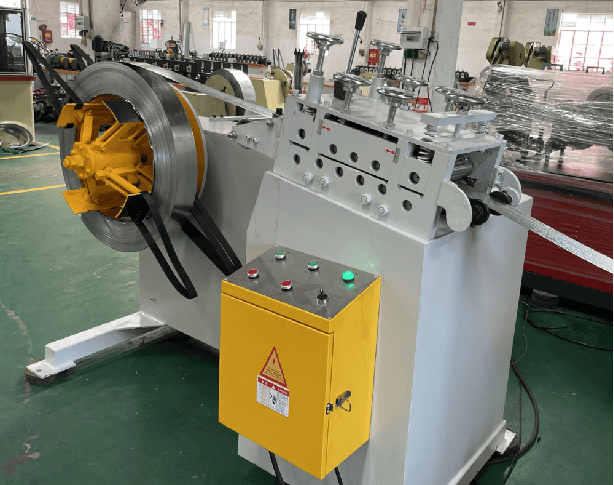

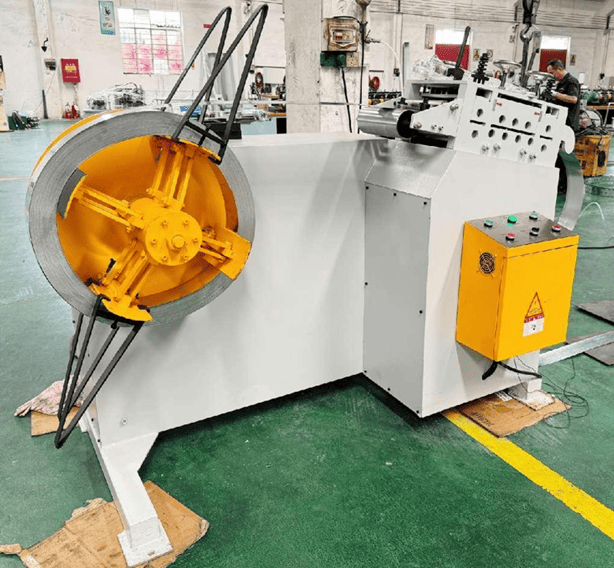

| Part 1&2: Hydraulic De-coiler & Leveling System | |

| Loading Capacity | 2 Ton |

| Application | It is used to support the steel coil and uncoil it in a turntable way. Manually tensioning and loosening, automatic feeding. |

| Coil Inner Diameter | φ460~520mm×200 |

| Coil Outer Dia | 1200mm |

| 2 in1 De-coiler | Combine the straightener and decoiler |

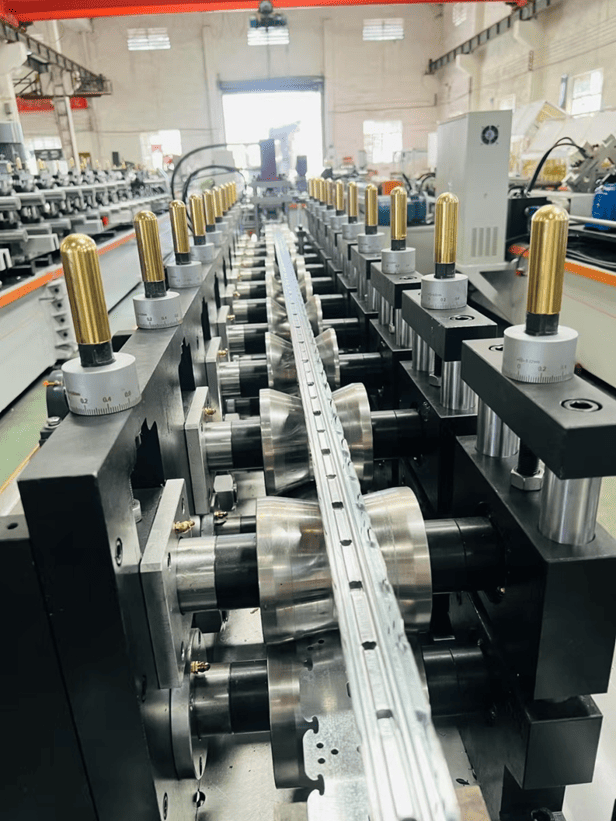

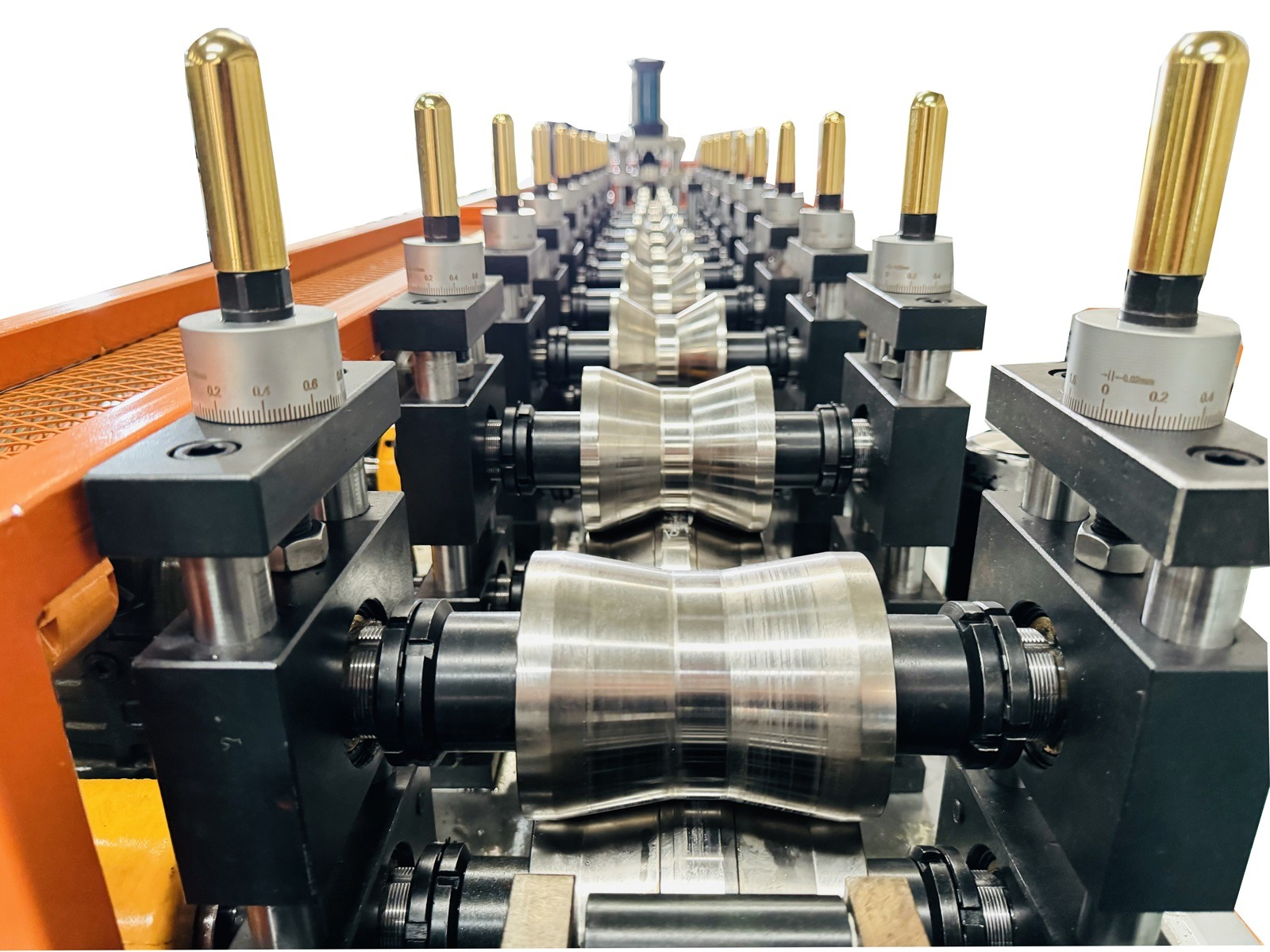

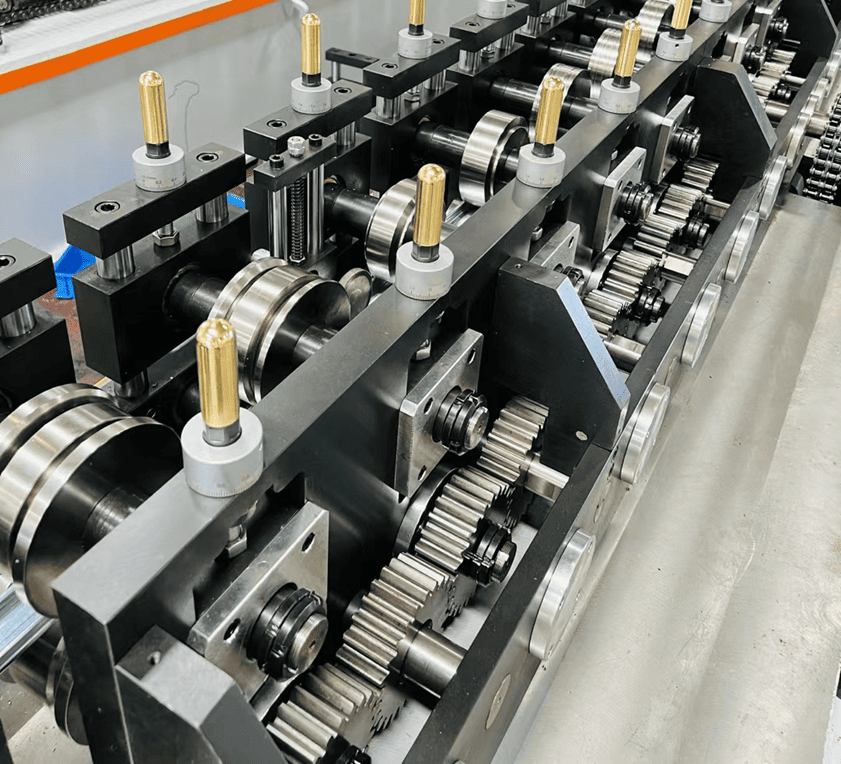

| Part 3: Roll forming system |

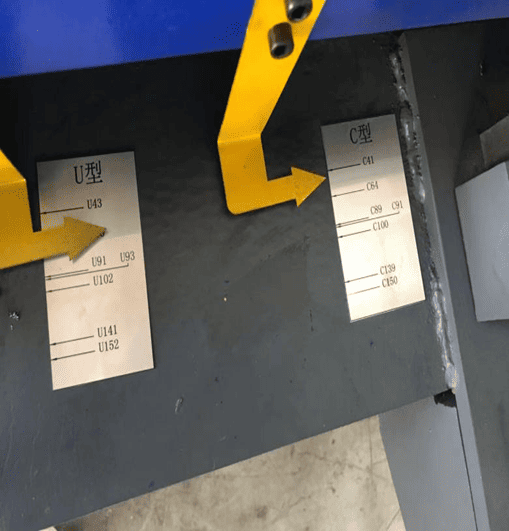

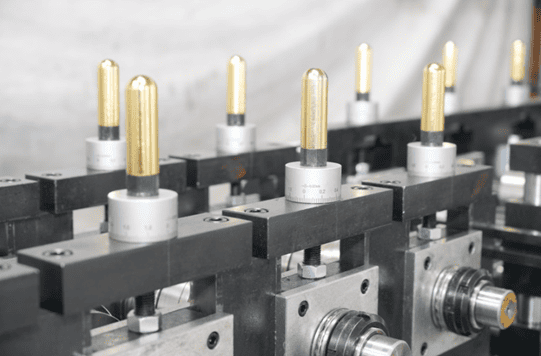

| Note: 1) The feeding part is easy for you adjust the feeding size when produce different sizes of products 2) The guiding device, easy for the material go into the machine smoothly and quickly. 3) Gearbox structure to guaranty the accuracy of forming and stable high speed forming 4) We use split rollers to make one machine to produce different sizes of drywall studs, you can adjust the size automatically by PLC |

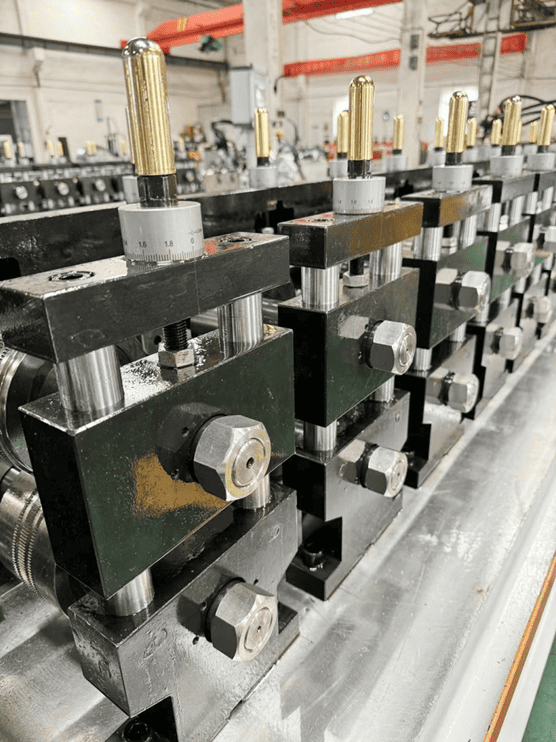

| Rolling shaft | Shaft material: 40Cr steel | Please check photos on right side, it is show you when you produce different size of stud or track, just adjust the wheel manually, the roller spacer will form to the size you need, and produce the profile you asked. | |

| Shaft diameter: 48 mm | |||

| Tempering treatment | |||

| Roller | Roller material: Cr12 mov | ||

| Quenched treatment | |||

| Rolling station number | 10 stations | ||

| Work speed | 25-50 mpm comprehensive, forming 60-80mpm(Punching speed 25-50 m/min, non-punching speed 60-80 m/min) | ||

| Machine frame | Base use high quality H steel; Vertical iron arch casting frame structure | ||

| Bearing | Chinese famous brand Harbin ( high quality) | ||

| Work power | 5.5kw+7.5kw | ||

| Transmission | By Gear box | ||

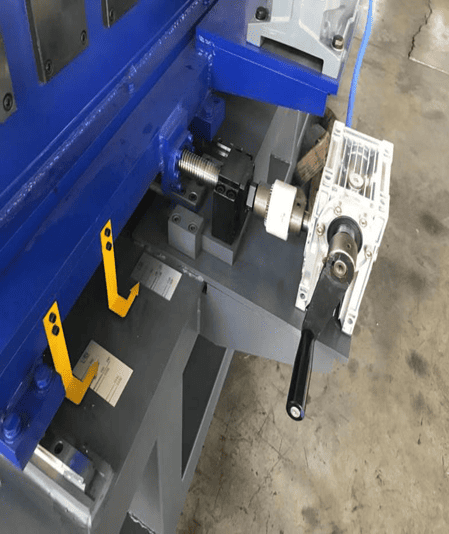

| Thickness Adjustment |

| This machine are designed to adjust the gap between top and bottom rollers by wrench. |

| Each roll forming station have installed a scale to indicate how many gap has been Adjusted. It helps to adjust the gap faster. |

| Use wrench to clockwise rotate the black nuts on the machine structure, the top rollers will move up a little bit. It does not take much time to adjust these nuts, experienced worker can easily to rotate the nut just by a second and when the worker feel certain resistance, it means the gap adjustment is done on this station. |

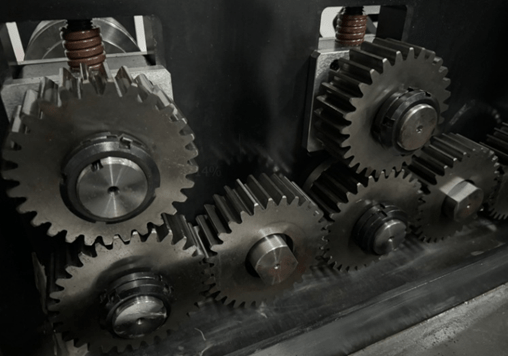

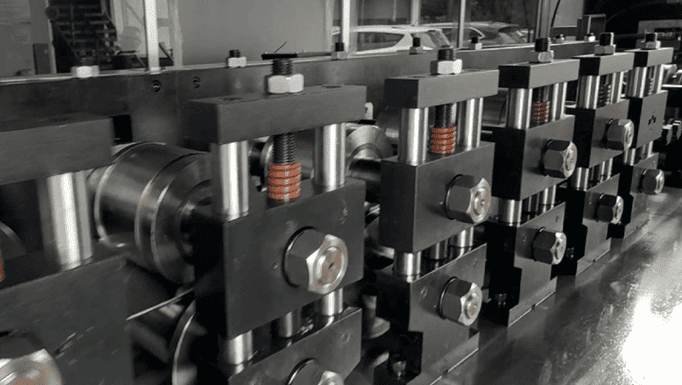

| Machine Driven |

| Gear + fine turning and grinding, the grade is the same as the gear of the car, the surface is smooth and flat, the gap is small, the precision of the machine running is higher, the machine running noise is quieter, and the machine service life is longer than those machimes driven by the normal gear or chain |

| Machine Frame |

| The frame is designed as strong as its required to bear the whole rollers and shafts. This ensure machine can work in long life without repairing any shafts and frames. |

| Machine frame basis is adopt H beam welding steel with leveling bolts in the basis to adjust the leveling. |

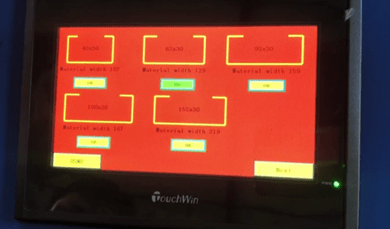

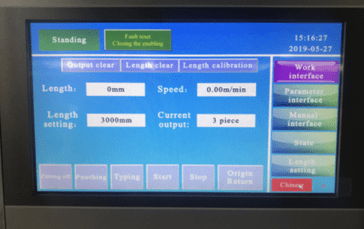

| Part 4: PLC Control System | |

| Note: There are two screens on the PLC control station, one screen is used to set the product size you want to produce, then the machine will adjust automatically according to what you set, another screen is used to set the speed, length and other specifications of the machine. | |

| Frequency brand | INOVANCE |

| PLC & Screen brand | INOVANCE |

| Screen type | Touch screen & buttons |

| Screen language | English/Chinese |

| Encoder | Germany SICK |

| Low pressure electrical part brand | Schneider |

| Function | 1. Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved; |

| 2. Length inaccuracy can be amended easily | |

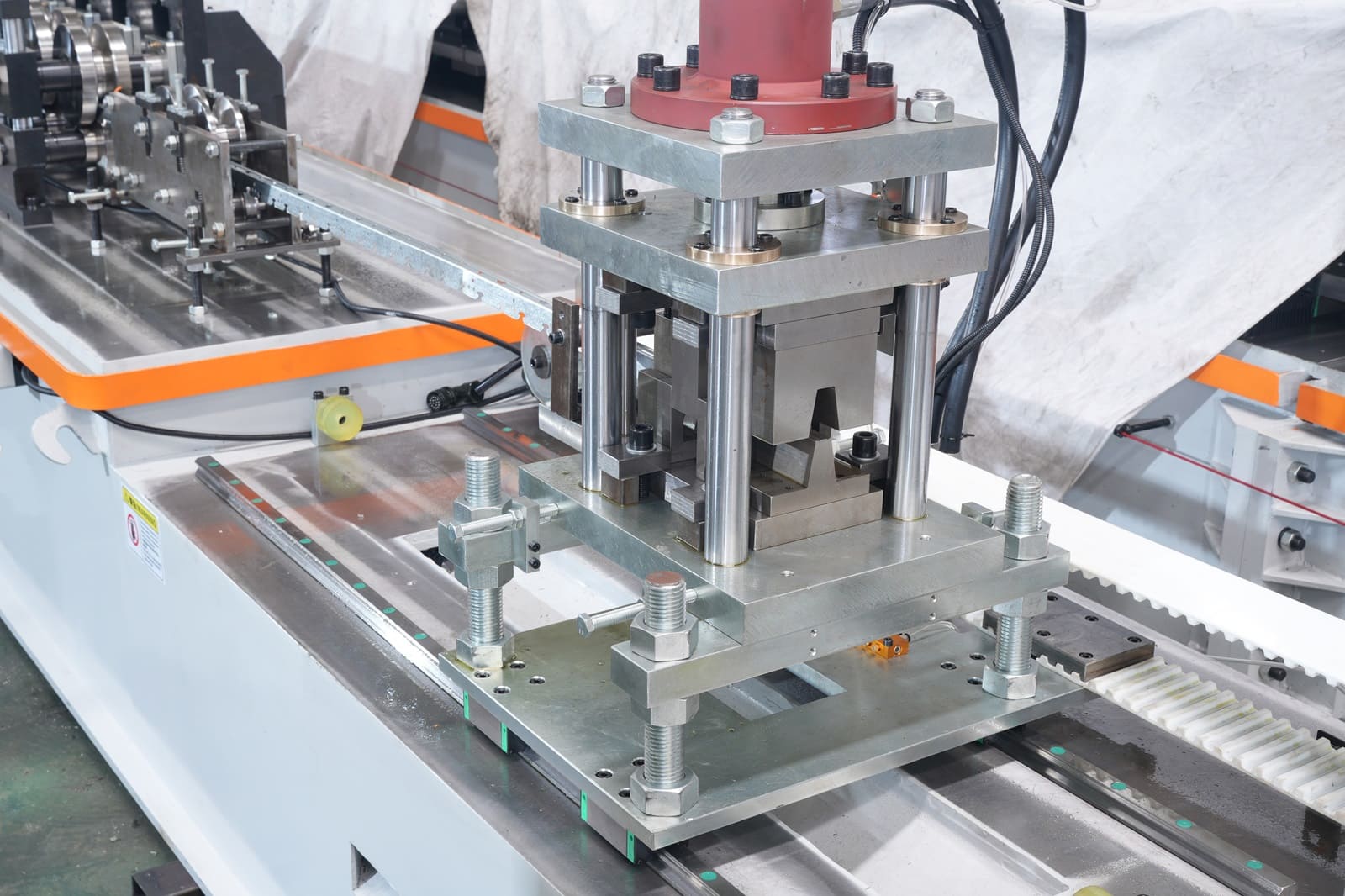

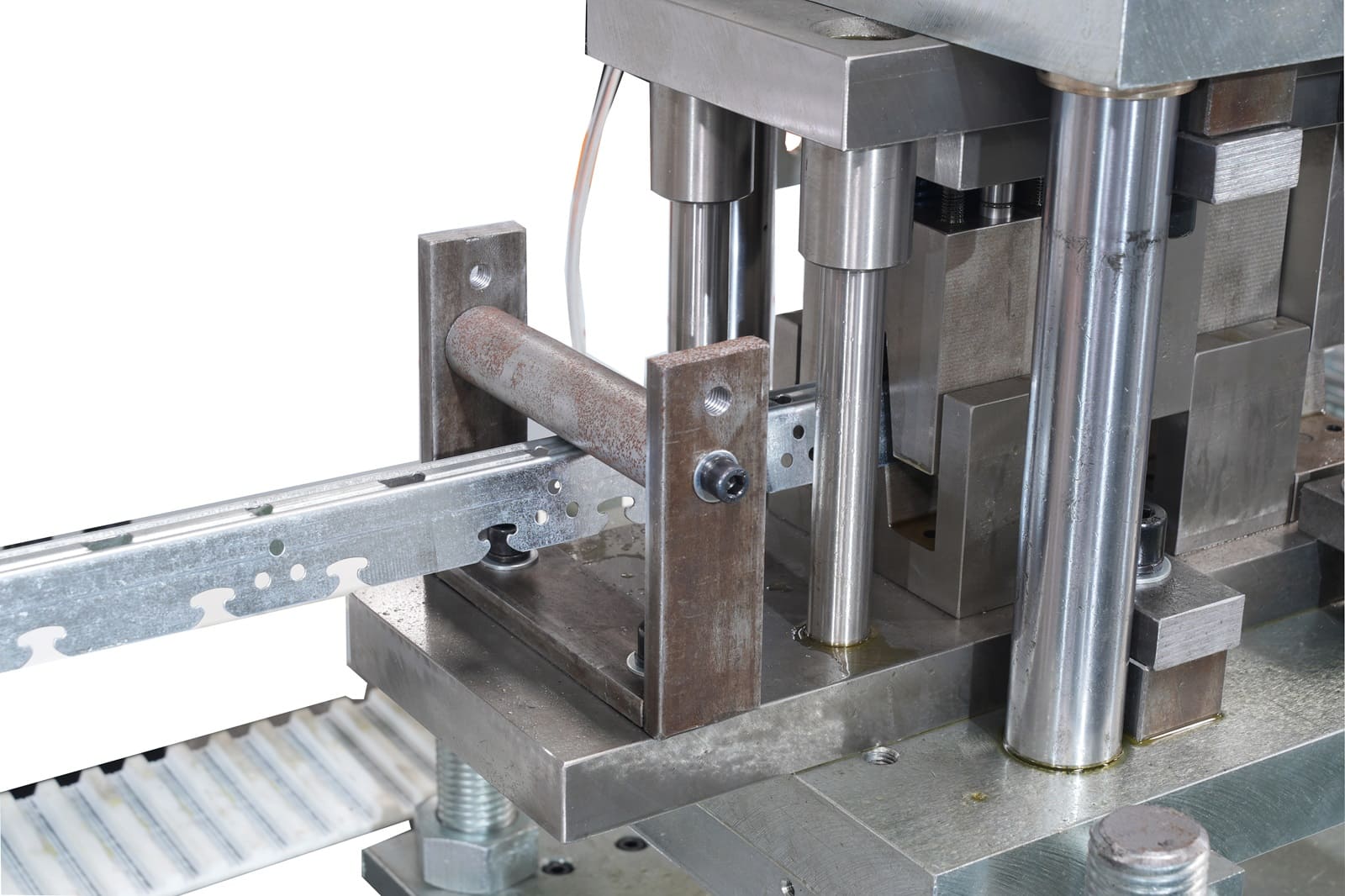

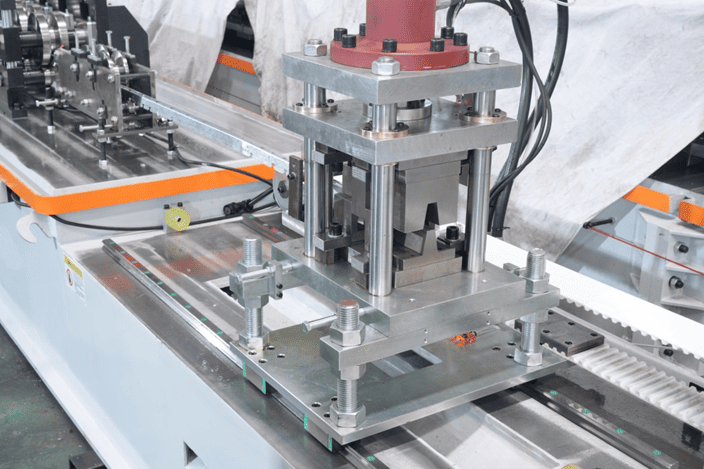

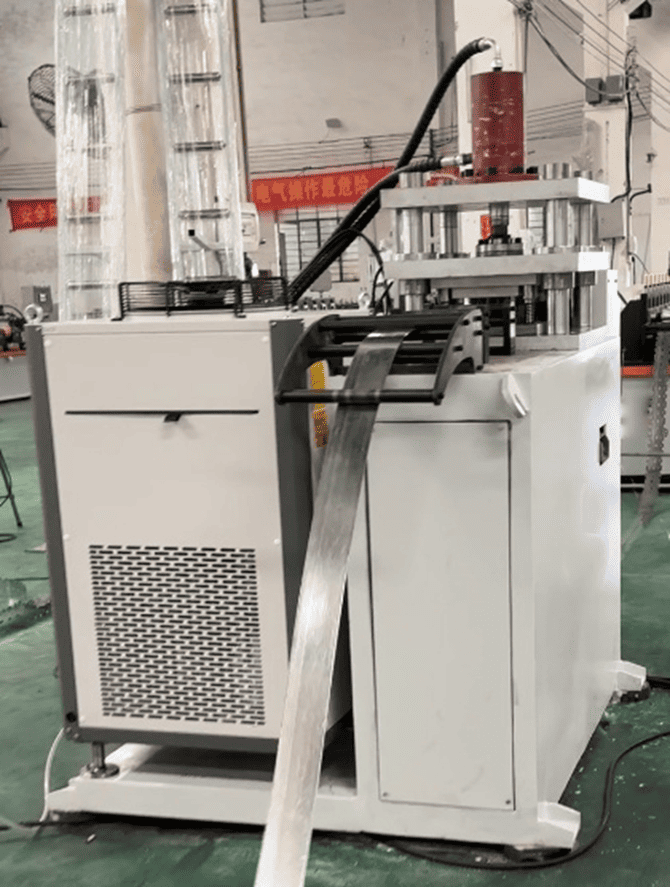

| Part 5: Hydraulic System | |

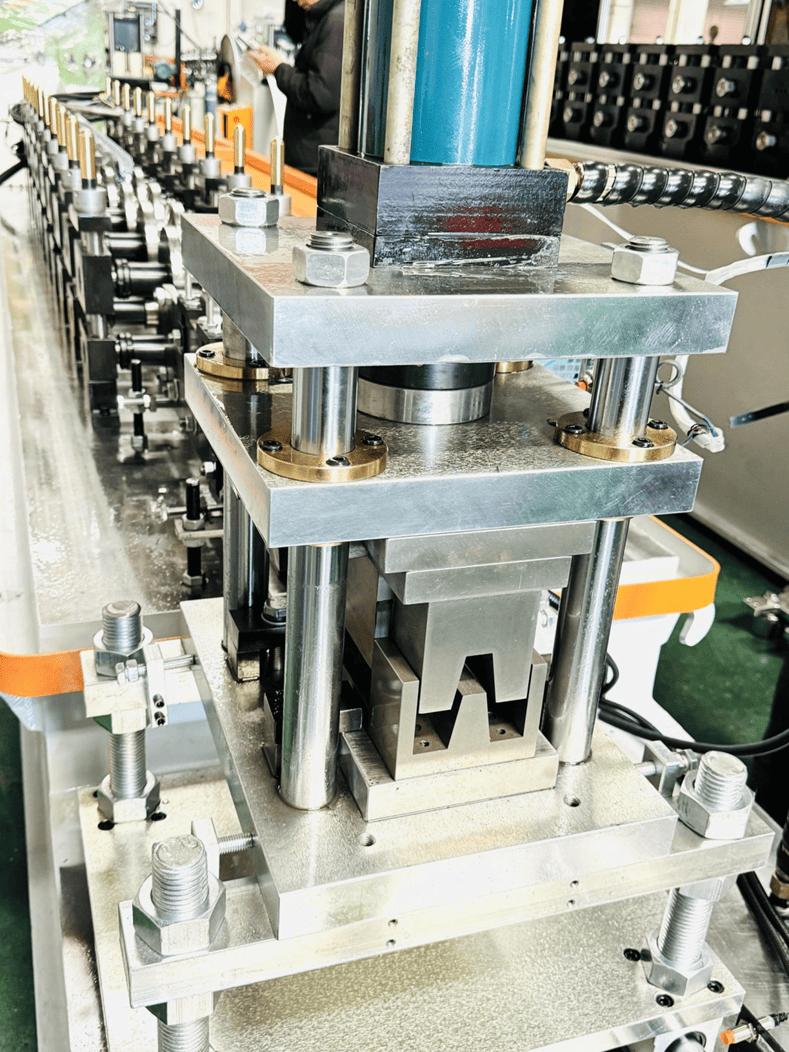

| Feature | The cutter with different sizes according to the product dimension. |

| Work type | Servo flying Hydraulic cutting system Hydraulic Punching system |

| Hydraulic power | 2.9 kw |

| Driving method | By pillar type Cylinder |

| Cutter material | Cr12 |

| Cutting length tolerance | ±1mm |

| Cutting feature | Flying shearing. When the machine cutting it will not stop |

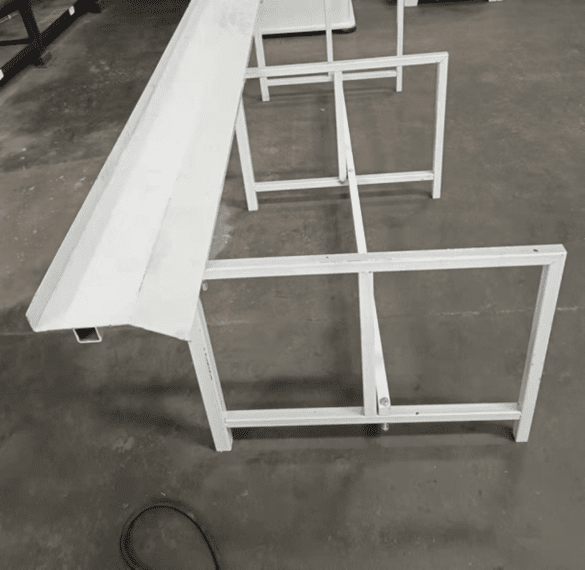

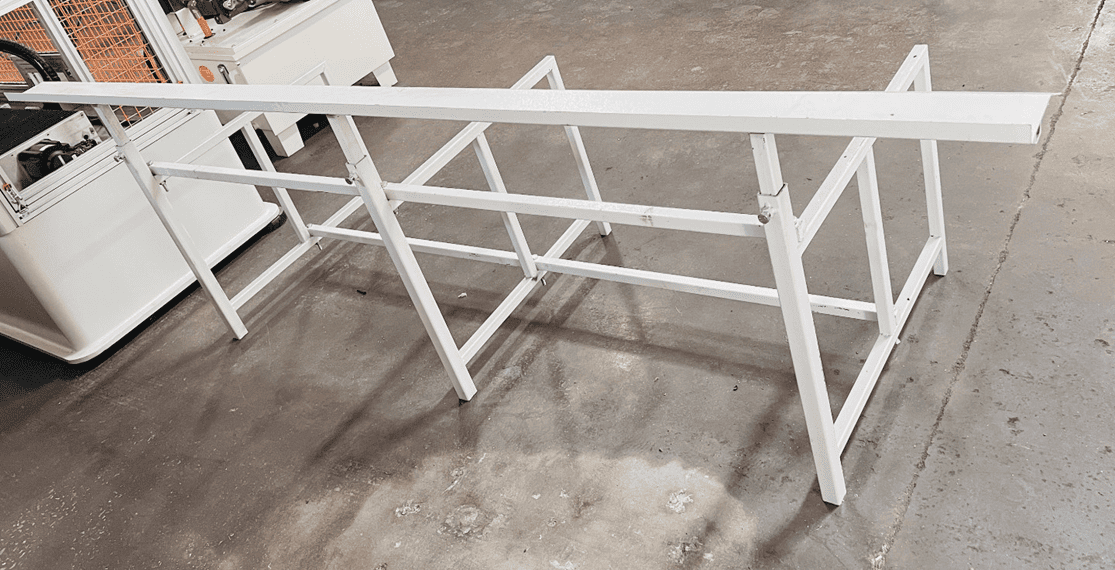

| Part 6 (optional): Product Support Frame | |

| Table quantity | 1 set |

| Size | Length 6m x Width 0.5m |

| Part 6: Automatic stacker & bundling machine | |

| This device automatically packs studs and track members and then auto bundles with belts. Then transfer the bundled studs to the ground conveyor. | |

| Table quantity | 1 set |

| Profile length | Within 4m per piece |

| Maximum speed | 70m per minute |

| Dimension | 8.5m x 2.5m |

Part7: Punch System (Hydraulic Punch)

| Machine safety cover+ fencing |

| Machine safety cover are an option for safety consideration. The roll forming station will covered with a complete safety cover with windows at both side of the machine. Other place like de-coiler, auto bundling and stacking machine will have fencing around. Once fence open or when the sensor around the machine detect human go inside the fence or get too close to the machine, the machine will stop automatically. |

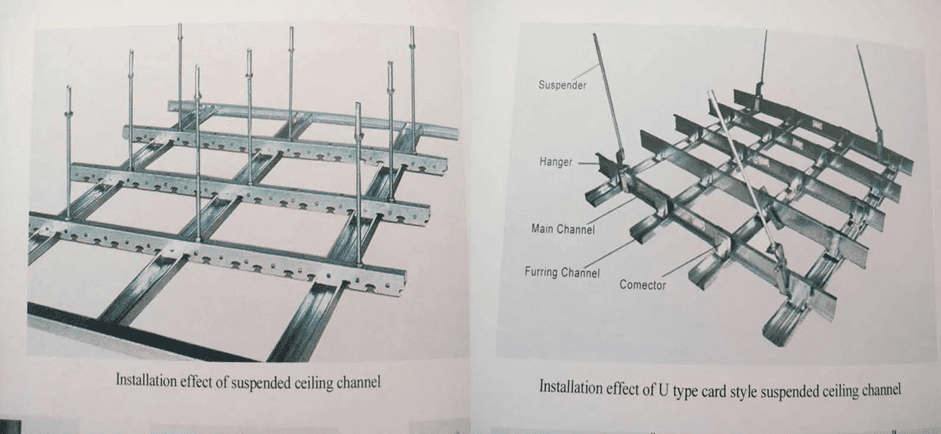

Application Types

| 1. C-Shape Channel Profiles, U-Shape Channel Profiles (Mostly used); 50mm Cross Profiles, 38mm Main Profiles C U Studs and Tracks 2. Wall Angle Profiles L-Shape Profiles 3. Furring Hat Omega Channels |

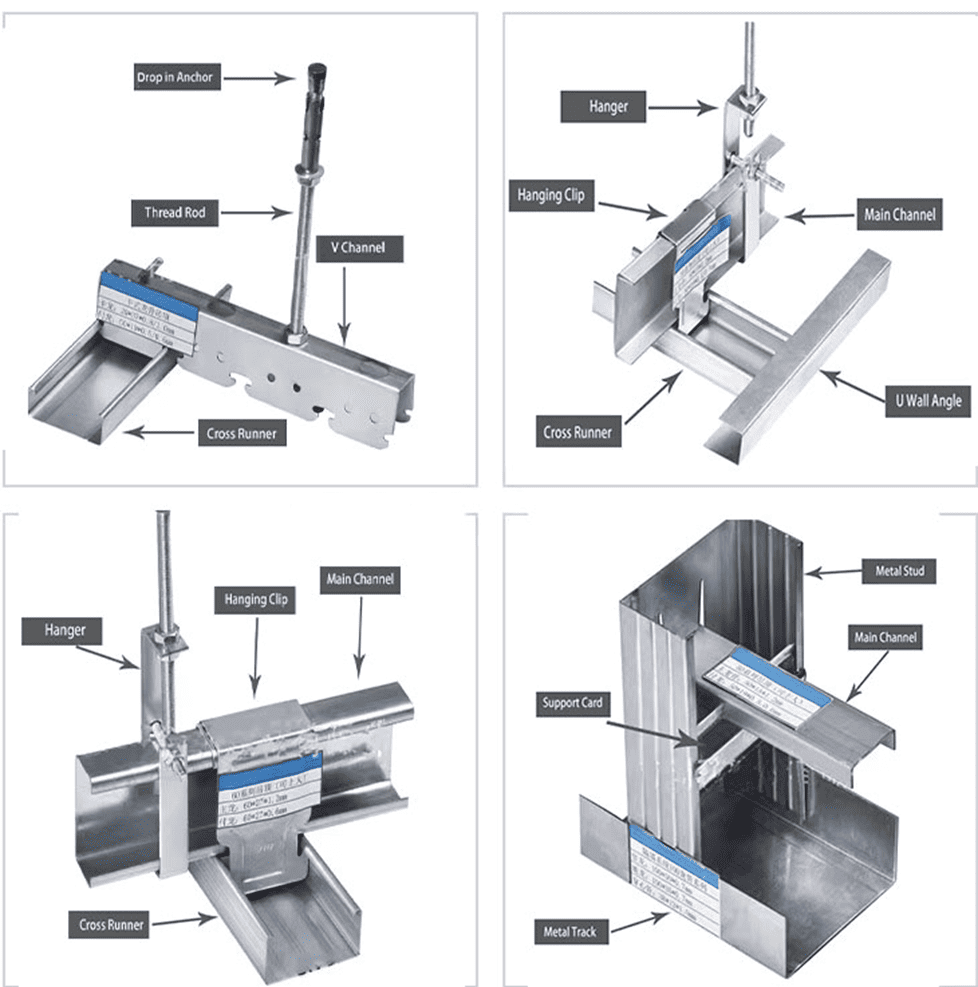

| Various ways to assemble suspended ceilings. When installing a linear strip ceiling, the linear strip ceiling carrier is an indispensable basic part. After the ceiling carrier is correctly installed, the linear strip ceiling is fixed on it to achieve the ideal decorative effect. The linear strip ceiling and the strip ceiling carrier together constitute the core of the ceiling system, and the coordination of the two directly affects the overall effect and performance. |

False Ceiling Framing Application Scenarios