Crimping curved machine for standing seam — the key to precision curves for designated preformed roof panels. This machine not only creates small, fine curves but also optimizes material usage, reducing costs for roof purlins and coatings. Crafted for durability, the curved roof panels enhance structural strength while delivering a beautiful and fashionable aesthetic. Elevate your roofing solutions with this efficient and cost-effective curving machine..

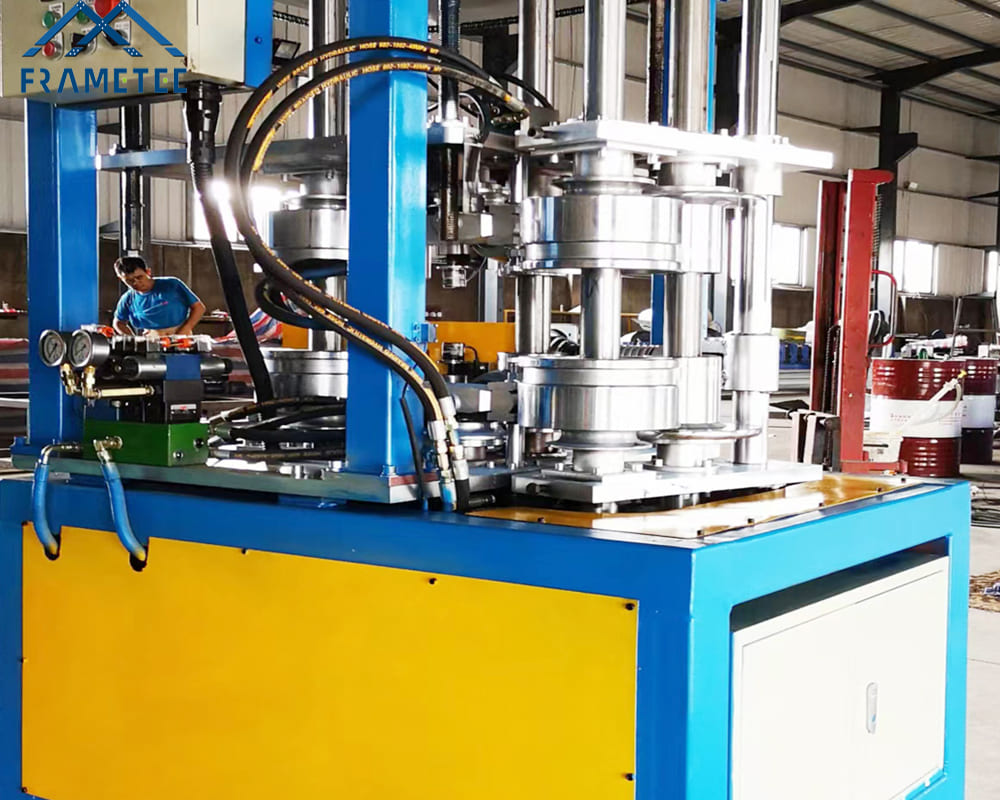

This set of equipment is a complete, brand-new forming and processing equipment. It mainly includes the main roll former, electrical control cabinet, and related accessories. we ensure that the set of equipment can meet the your product technical requirements and provides relevant technical support and after-sales service during use.

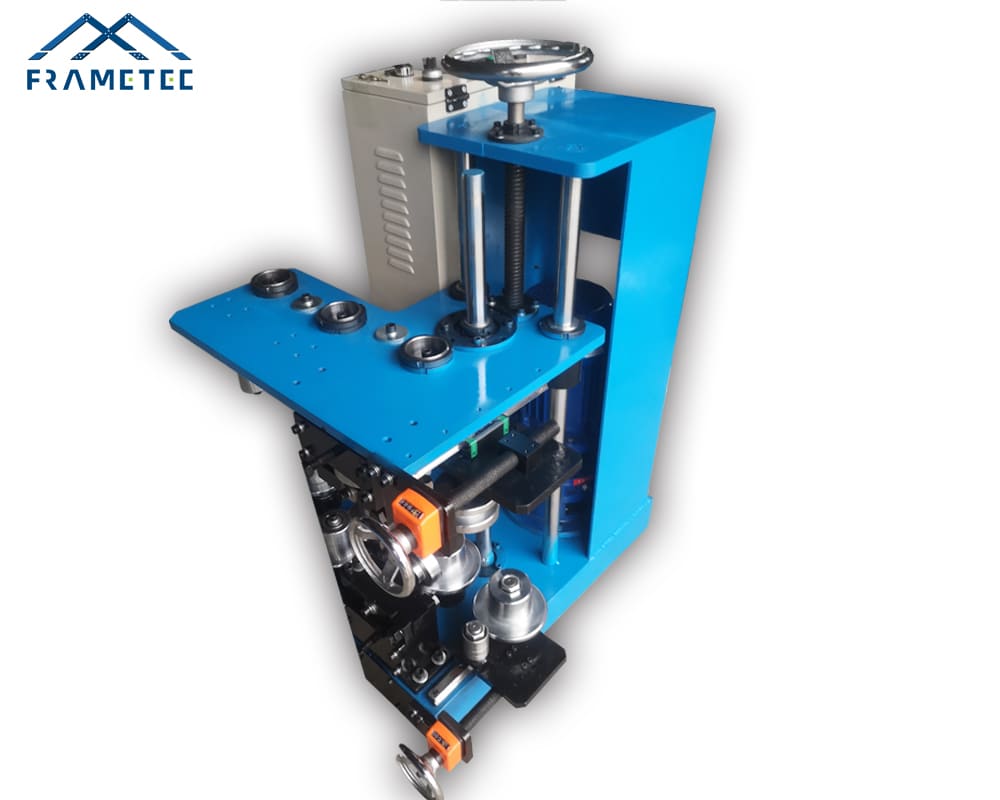

Machine Part

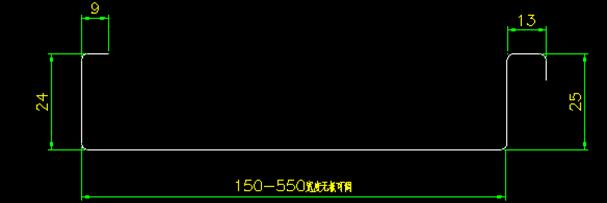

Ⅰ、Specifications

| Machine model | KLS25-550 Curving machine Crimping machine for Standing Seam |

| Coil Width | 220-550mm Straight & taper profile |

| Material Thickness | 0.6-1.2mm ( different material with different thickness range) |

| Main Motor | 1.1KW |

| Forming Station | 4 steps |

Note 1: The hand screw can be adjusted to adapt to different finished product widths, with an adjustable range of 220-550mm.

Note 2: For the first plate, the bending radius needs to be manually adjusted several times before it can reach the required radius. Follow-up

Starting from the second piece of board, the arc is formed in one step. If you need to bend to a smaller target radius, you may need to bend the arc 2 or 3 times depending on the arc material. The shapes of the male and female edges are different, and the handwheel adjusts the radius differently.

Note 3: For one plate, only one arc radius is made. Not suitable for multiple radii.

Note 4: It is recommended to bend only positive arcs on a board, and reverse arcs are not recommended. It is also impossible to integrate forward and reverse arcs on one board.

The radius of a primary bending arc is as follows:

Color steel plate: thickness 0.6mm, minimum positive arc radius ≥8 meters, minimum reverse arc radius ≥10 meters

Color steel plate: thickness 0.4mm, minimum positive arc radius ≥10 meters, minimum reverse arc radius ≥12 meters

Aluminum magnesium manganese plate: thickness 0.7mm, minimum positive arc radius ≥1 meter, minimum reverse arc radius ≥3 meters

Aluminum magnesium manganese plate: thickness 1.2mm, minimum positive arc radius ≥2 meters, minimum reverse arc radius ≥5 meters

Special note: The steel plate is curved and is lower than the limit arc, so it is easy for the plate surface to bulge.

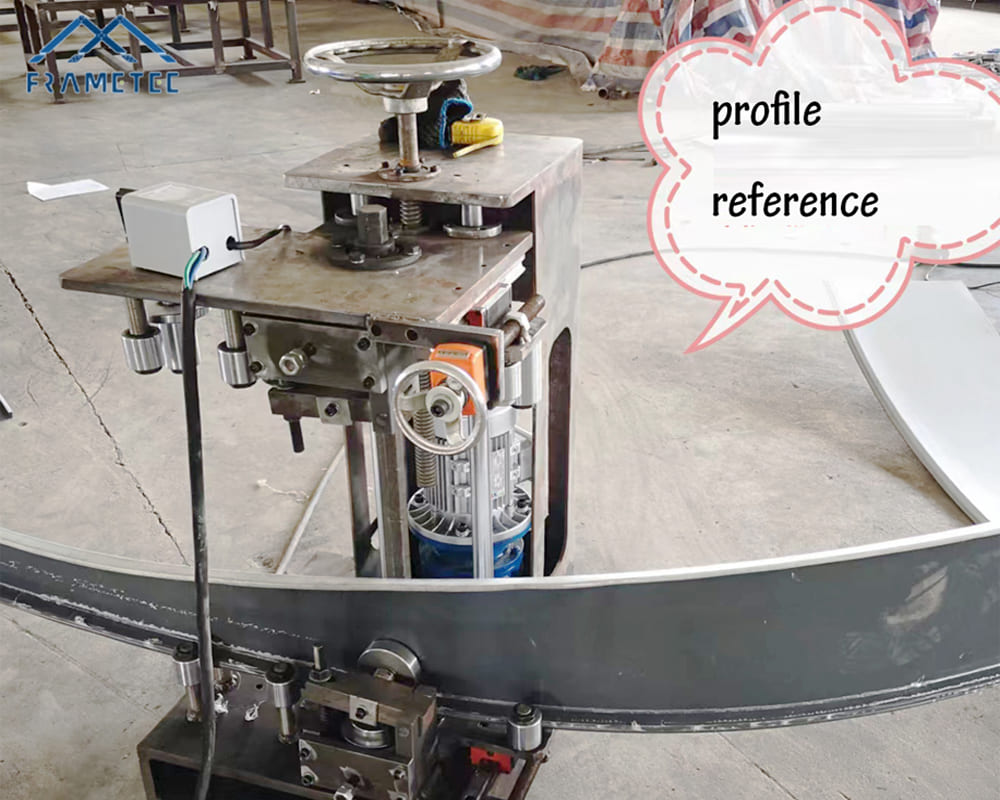

II. Machine Video

III.Profile details

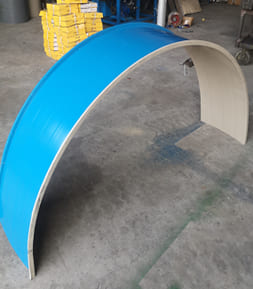

Profile effect:

Transportation Package:

Our Factory: