Features of C/Z purlin machine:

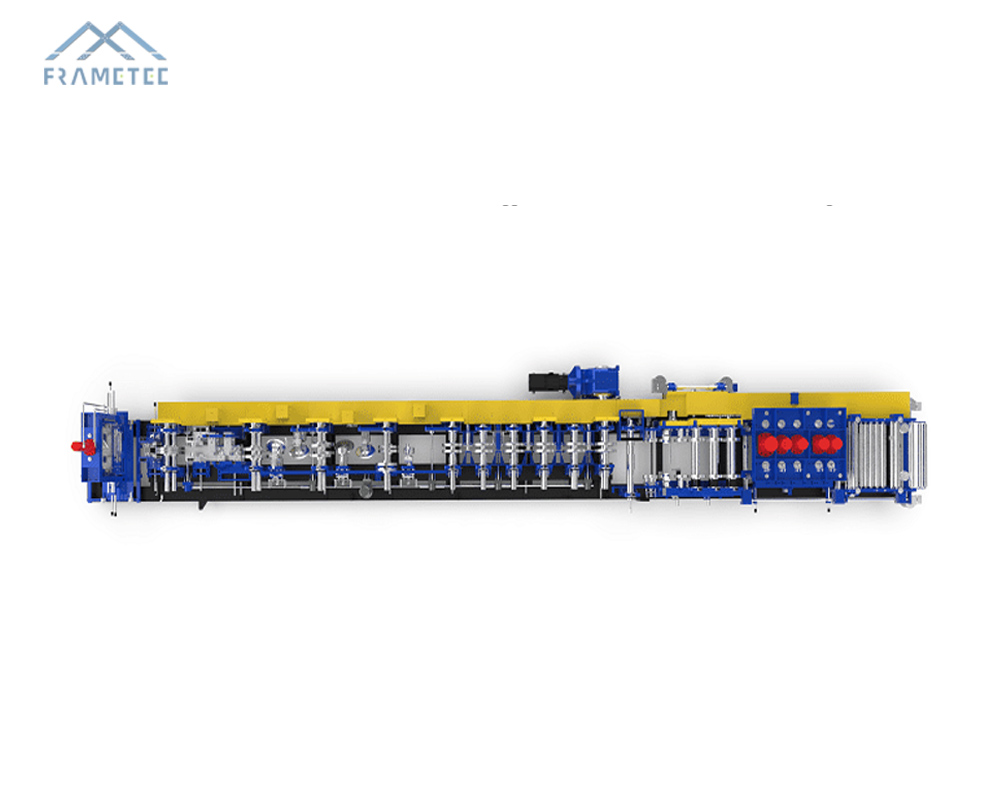

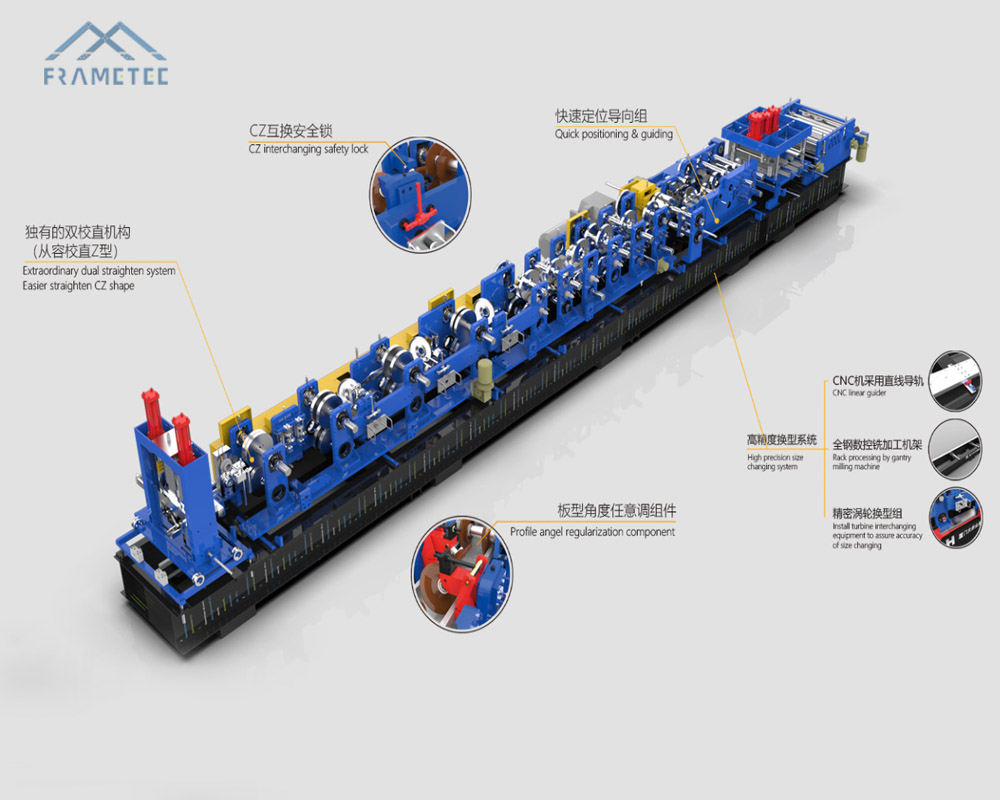

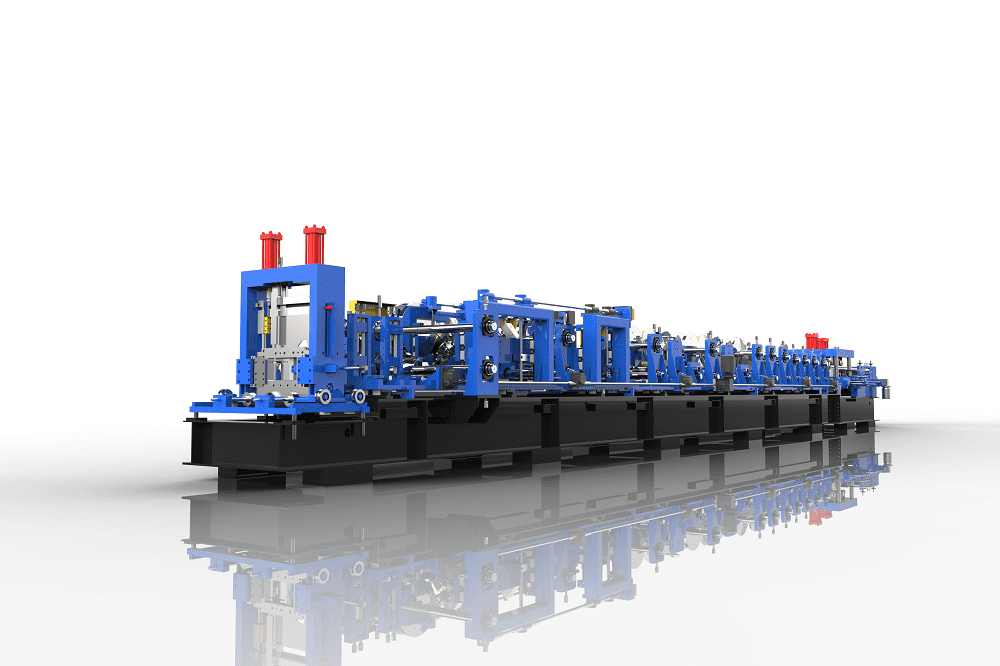

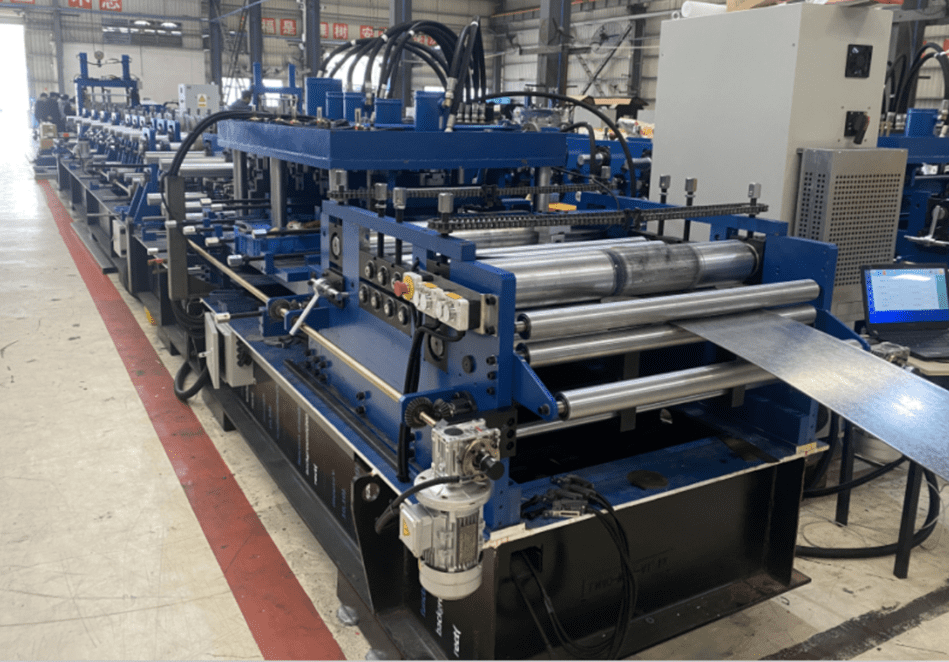

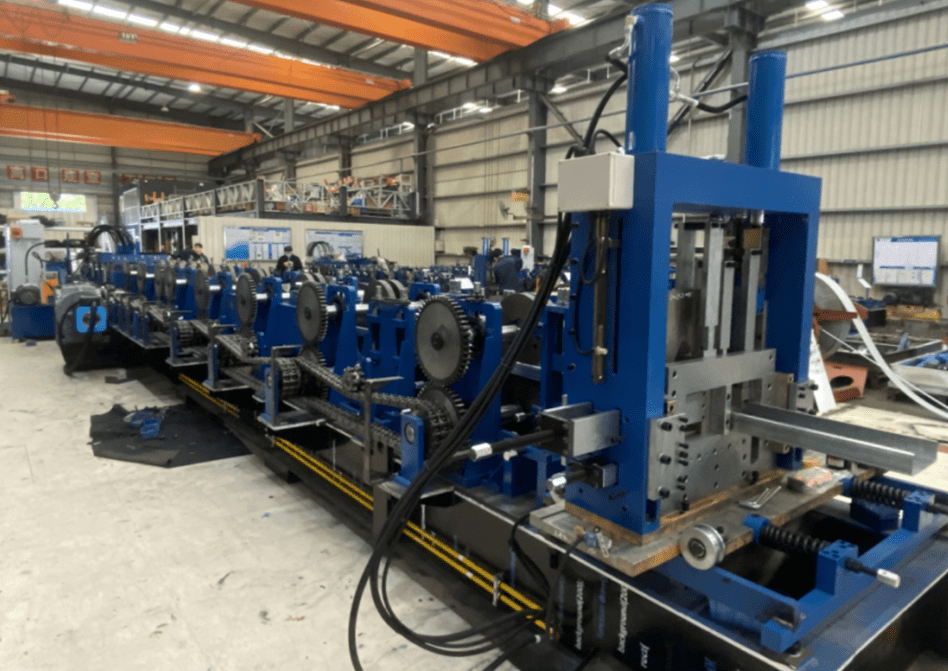

Our NLT400 C/Z purlin machine consists of decoiler, feeding and levelling device, punching system, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system). Its special quick change feature: Assemble with liner guide way to make machine change web size easily and smoothly

Produce standard products with yield strength up to 345Mpa, Long production line, better profile shape control on final products, C/Z interchange only with 3 steps and within 5-15 mins; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

| Machine Quick Details | |

| Model number: NLT400 | Condition: New |

| Type: C/Z Purlin machine | Brand Name: Frametec |

| Max Production Capacity: 35M/min | Power(W): 55KW |

| Warranty: 1 year | Place of Origin: China |

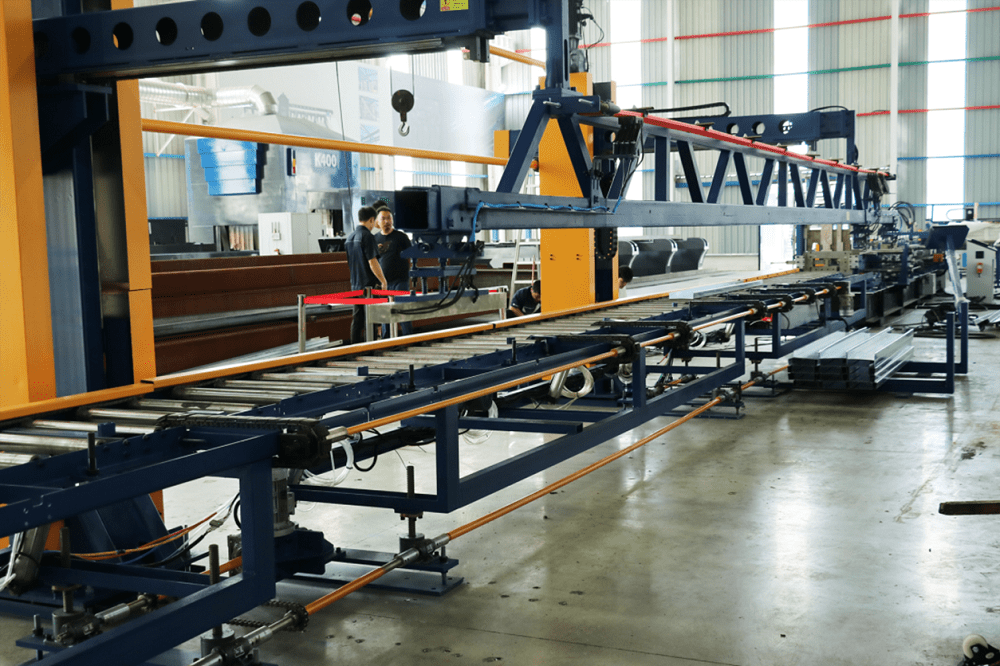

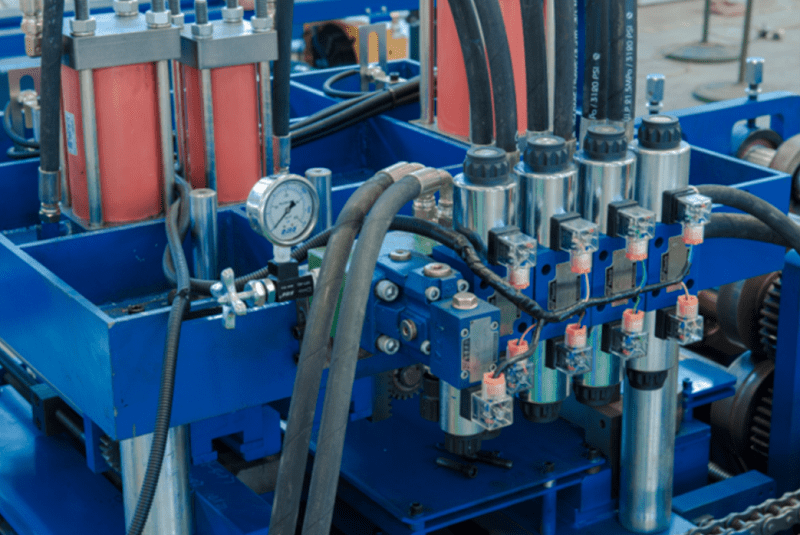

Flow chart: De-coiler – Leveling device — pre- punching and pre-cutting – roll forming parts – stack

Main features of quickly change CZ purlin roll forming machine

The Advantages of CZ purlin machine AUTOMATIC size-change type are as follows:

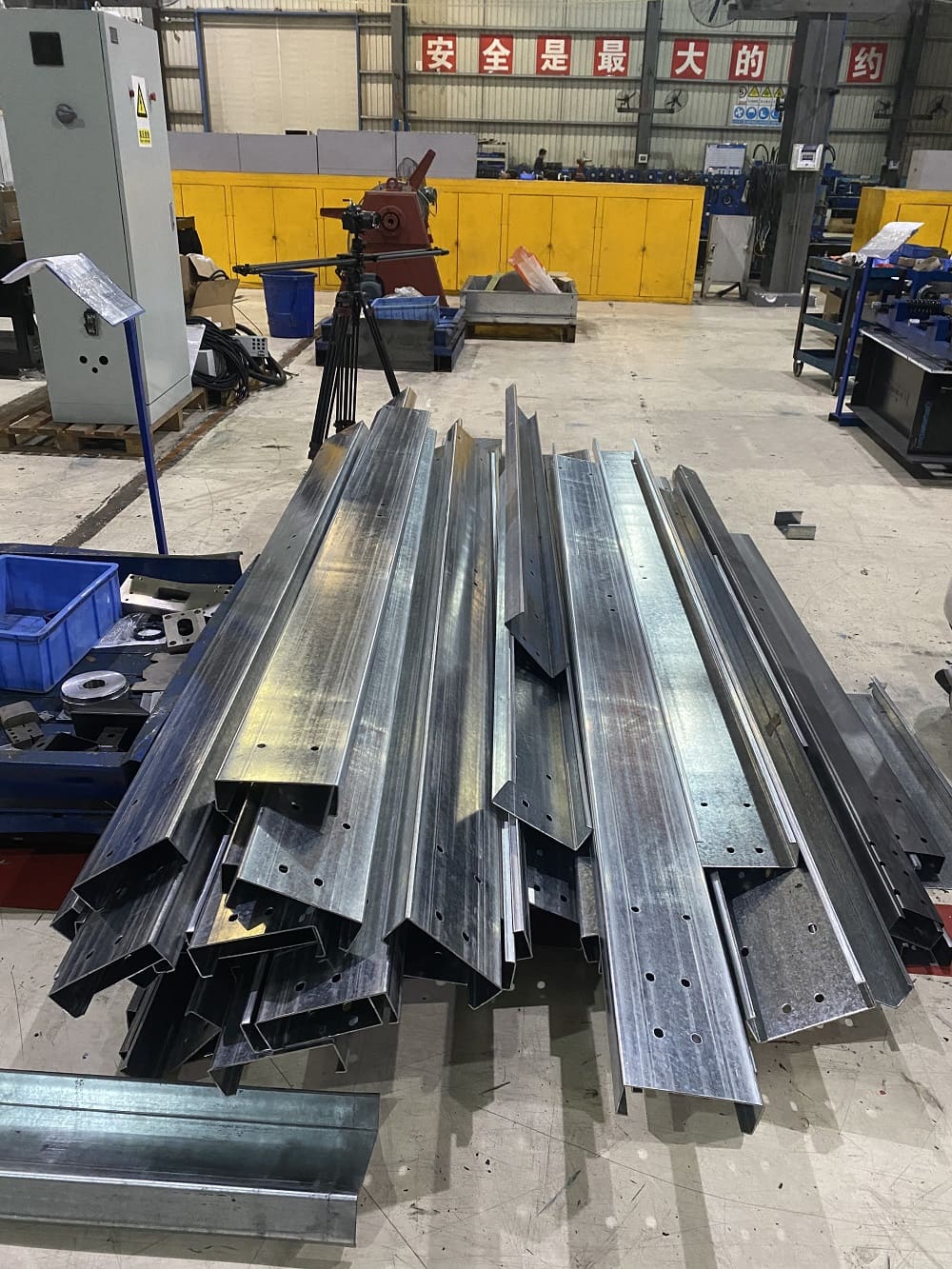

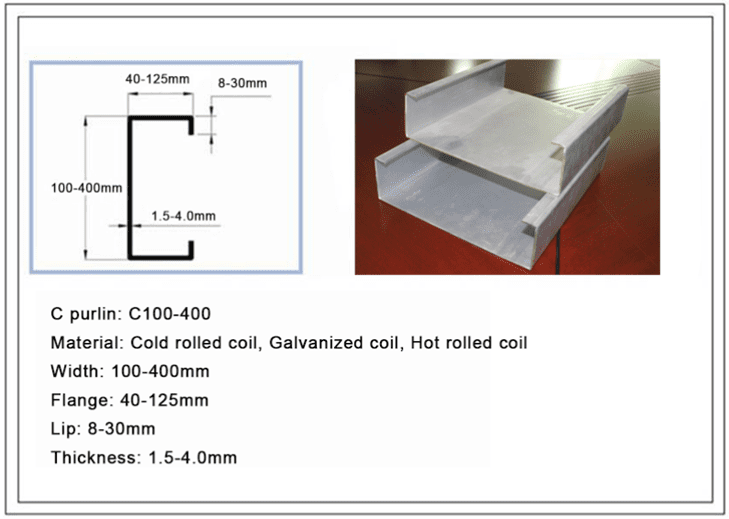

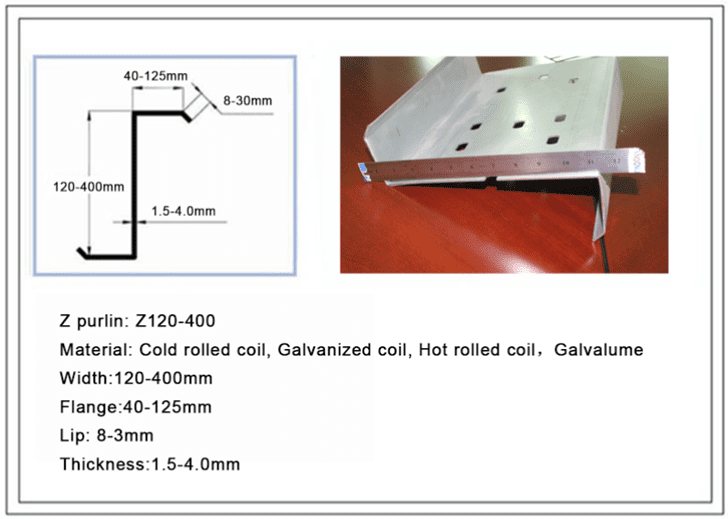

1.Produce different purlin size(C100-400/ Z120-400) without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

Main Components:

1. Hydraulic De-coiler

De-coiler Type: automatic fasten and loosen

Weight capacity: 8T

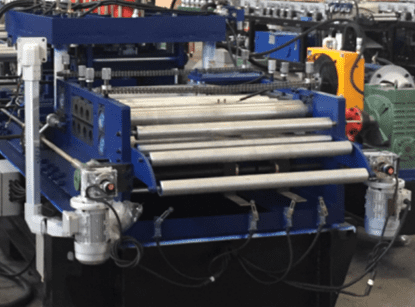

2. Feeding and Leveling Device:

It used for making the material flat before feeding into the roll forming machine.

3.Pre-punching device

Punch on flat sheet. PLC control punch quantity and horizontal position; vertical position adjust by manual.

Web punching quantity& size: as per customer`s requirement

Flange punching quantity&size: as per customer`s requirement

Punching bar and punching die can be changed easily

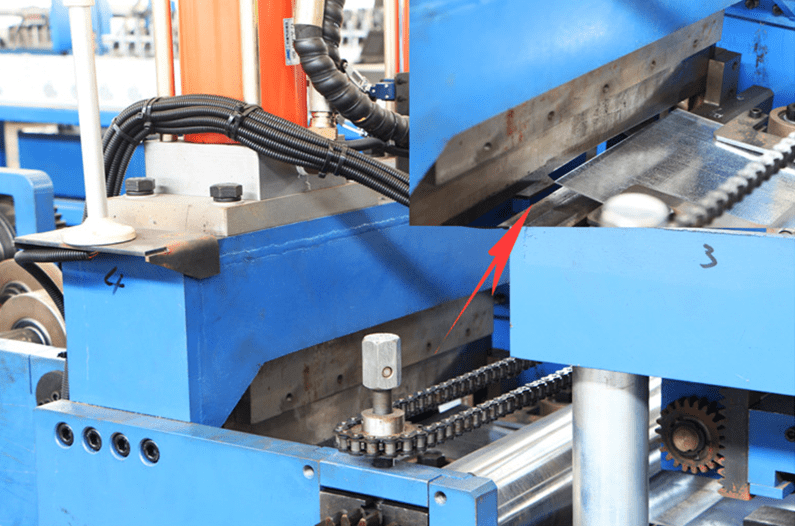

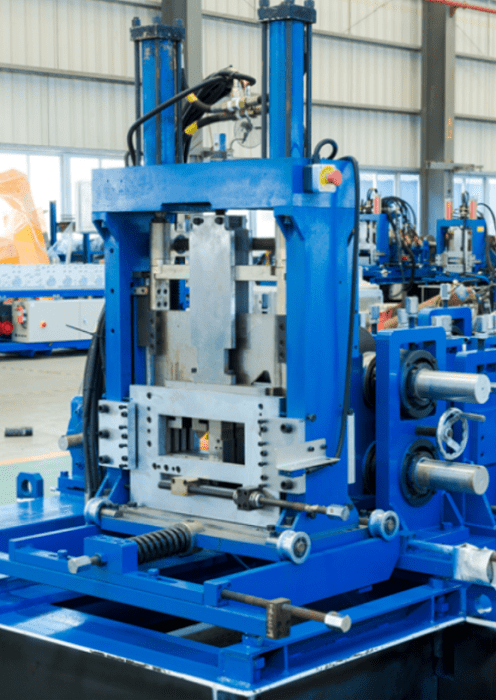

4.Pre-cutting device

It used to cut raw materials before roll forming.

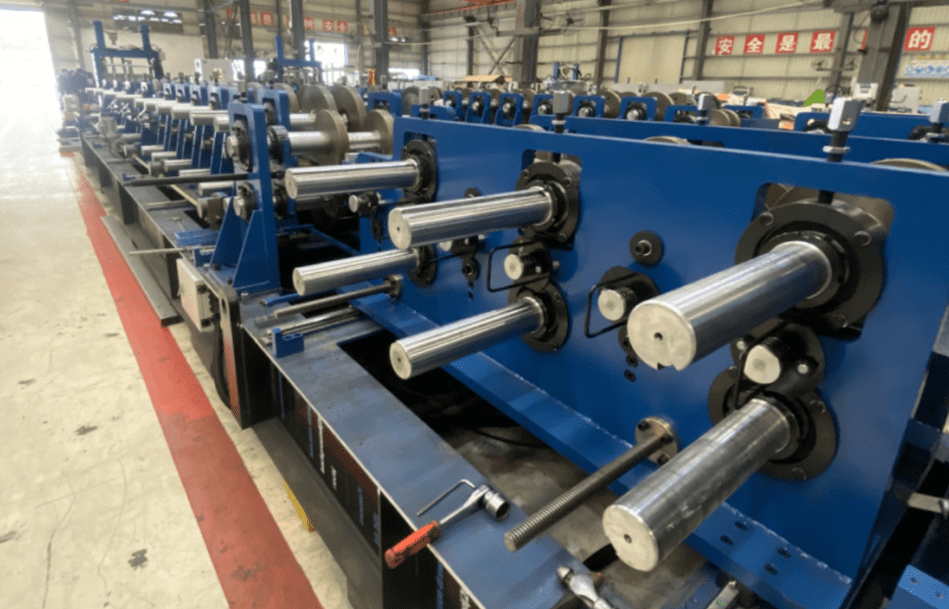

5.Main roll former

Driven type: By gear boxes

Max Speed of forming: 30m/min

Roller : About 24 groups rollers

Roller Material is Cr12 mould steel;

Diameter of down roller is around 360mm

Shaft: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product. Diameter of main shaft: ø95mm (as per final design)

Material of main shaft : 40Cr

Changing sizes: Full-automatic

Adopt fast C/Z interchanging system

Quick C/Z interchanging only with 3 steps,within 5 -15 mins.

6.Hydraulic Cutting

Adopt our innovative cutting system, CZ integrated & adjustable cutting mold do not need to replace cutting mold when purlin sizes change.

7.Product Support Frame —1set

8.PLC Control System

Control the quantity &punching length& cutting length automatically

The Machine will be stopped while it is punching and cutting

Automatic Length measures and quantity counting (precision +- 3mm)

Profile effect:

Why Choose us:

13 years’ manufacturing experience in CZ purlin roll former

Competitive price and good quality

One year free warranty

Fast response of after sale service

Auto web size changing from 80mm to 350mm in 2 minutes

Can be customized by clients’ requirements

Easy operate and easy to maintain

Self-developed of post cutter, one blade to cutter all size of final products