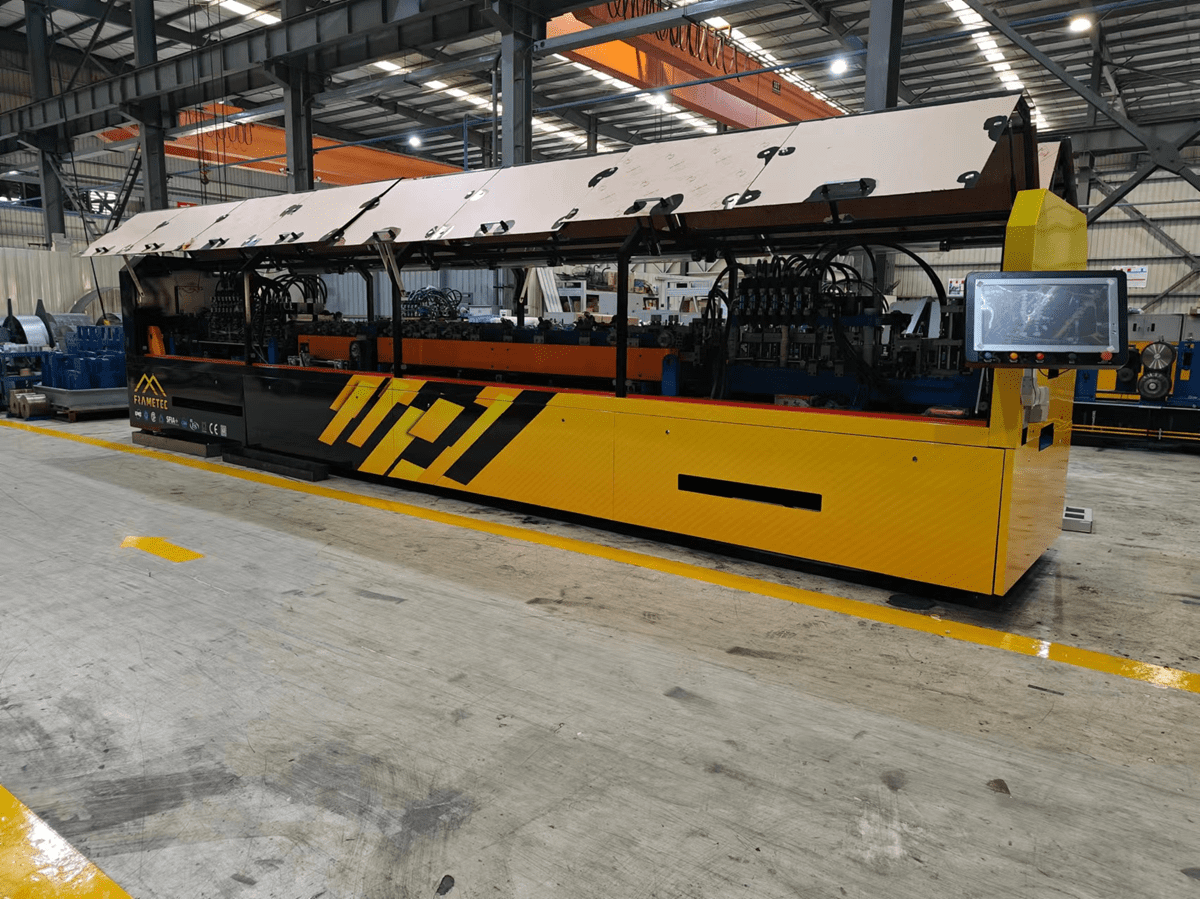

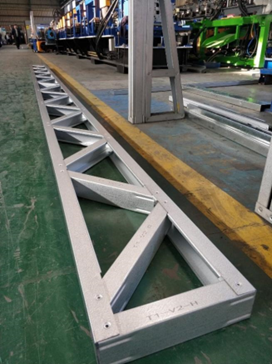

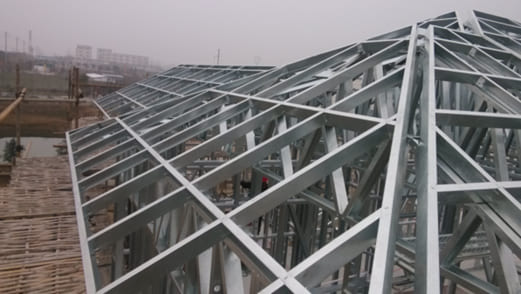

If you are looking for a machine that can make the wall panel 89mm, roof trusses with 75mm, special floor joist system with 250mm, and all can with the full function holes punching & cutting with CC connection. Then SFS-CC75-250 is an ideal for you, it combines the advantages of MF200, MF1600 and LG300, width range from 75-250mm, thickness range from 0.8-2.0mm, making it ideal for many residential and commercial applications.

Applications: construction walls, floors and roofs for 1–5 level residential, modular house, transportable units, light commercial construction and custom buildings.

Machine Part

Ⅰ、Specifications

| Profile Shape | CC |

| Profile Size | 75-250mm |

| Material Thickness | 0.75-2.5 mm, G300-G450 Zinc-Alum Steel Coil |

| Operation System | 21 inches Touchable Screen |

| Production Control System | Self-devoloped FrameTec LGR1 machine controlling Software |

| Design Software | Vertex BD/ Framebuilder MRD / Strucsoft & etc. |

| Comprehensive Machine Speed | Joists: 500 m/hr Walls: 800 m/hr |

| Max. Machine Speed | 2,150m/hr |

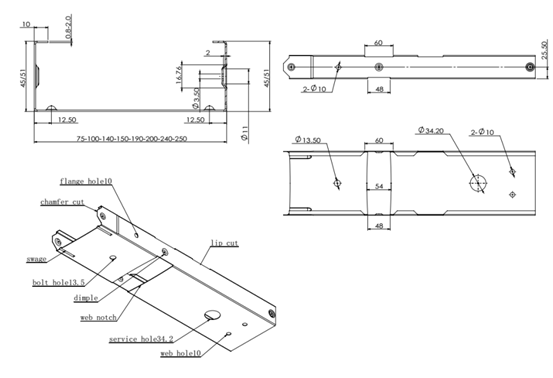

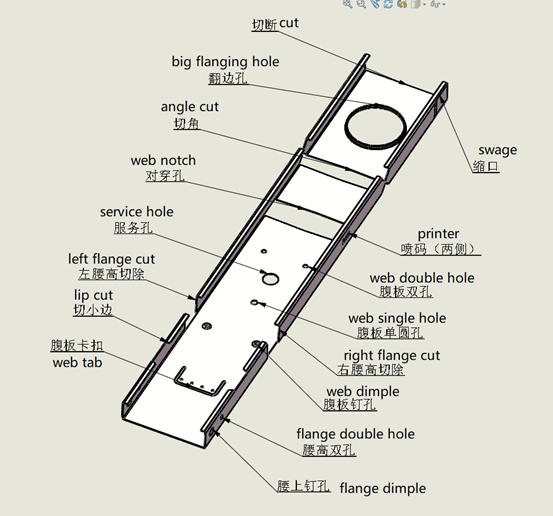

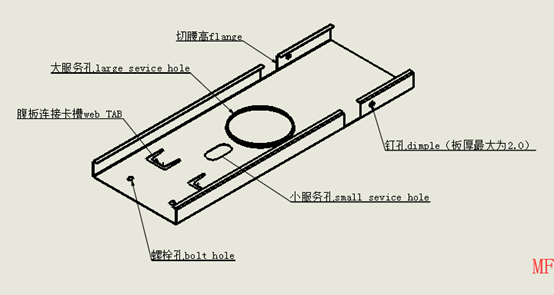

| Punching, Cutting Mould | dimple hole, Chamfer cut, Web notch, lip cut, service hole, bolt hole, big flanging hole, flange cut, web hole, web tab, large service hole and shearing |

| Hole Punching Accuracy | ± 0.5 mm |

II. Machine Video

III. Machine Main Features

| 3 in 1 machine that can make special wall panel, roof truss and floor joists | Strong performance, professional and advanced, Equipped with a powerful 22KW servo motor drive |

| The high-speed 35m/min output speed demonstrates the beauty of simple and complicated technology | The power and energy efficiency of the 11KW main hydraulic station has been greatly improved |

| High line speed results in the accelerated cold formed steel framing and truss manufacturing output | Smart internet connectivity provides cloud-based data reporting to enable real-time production management, and technical diagnostics to improve efficiency |

| LG-R1 Light steel framer dedicated CNC NC control software | Self developing control system base on the market feedback that can meet your requirement well & with good after sales support |

IV. Machine Details

V. Profile Effect & Application

VI. Why Choose FrameTec

FrameTec- a specialized manufacturer of high-quality roll-forming equipment for constructing light steel frame structures & cold-formed steel structures.

Since 2009, FrameTec insists on cooperating with customers as a partner and actively provides effective solutions to ensure reliable product performance, advanced technology and easy operation, and promote users to a higher position in the fierce market competition.

All Frametec machines have a built in Windows based machine control which accepts a basic CSV file from a range of design software options that link to our machine. This gives freedom of choice to the customer.

FrameTec specializes in Designing and Manufacturing Steel Framing Machines for Wall Panels, Trusses and Floor Joists in:

- Residential and Commercial buildings

- Steel framed systems for modular & prefabricated buildings

- Walls framed for low and high rise buildings

- Walling, floors, beams, roofing, kitchen & bathroom pods

- Storage, recreational, transportable dwellings

FrameTec, the intelligent manufacturing solution provider for multi-storey prefabricated buildings !