KLS25-530 Standing Seam Forming Machine – a pinnacle of precision and efficiency. Automated by a computer system, this compact machine boasts a robust structure and utilizes a reducer for seamless roll forming and hydraulic cutting. With a maximum speed of 25m/min, it ensures swift, stable, and accurate production. Crafted with a reasonable structural design and durable materials, this machine guarantees high stability, short delivery times, and exceptional cost performance. Elevate your manufacturing prowess with the KLS25-530, where innovation meets reliability for unparalleled standing seam forming efficiency.

Machine Part

Ⅰ、Specifications

| Machine model | KLS25-530 Standing seam |

| Coil Width | 300-600mm |

| Material Thickness | 0.5-1.0mm, Q235mpa Aluminum magnesium manganese plate and titanium zinc plate |

| Main Motor | 4KW with 4# reduction box |

| Production Control System | Self-devoloped Controlling Software |

| Forming Station | 8 steps & extra group forming wheels |

| Production speed | 0-25m/min |

II. Machine Video

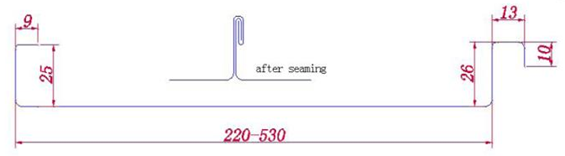

III.Profile details

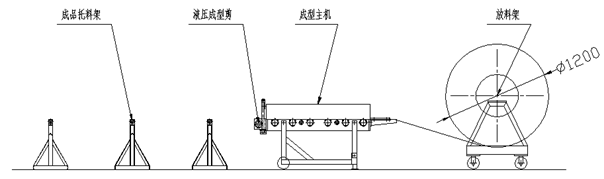

Flow chart: De-coiler – roll forming parts –hydraulic cutting- stack

IV. Main Components:

5t Manual Decolier For Free

Work type: passive type Structure: Steel channel welded for the basic frame Usage:To support the coil and make the uncoiling Loading capacity: 5 tons Inner diameter: 470-530mm (manual adjustment) Coil width: 1250mm Brake system: manual brake

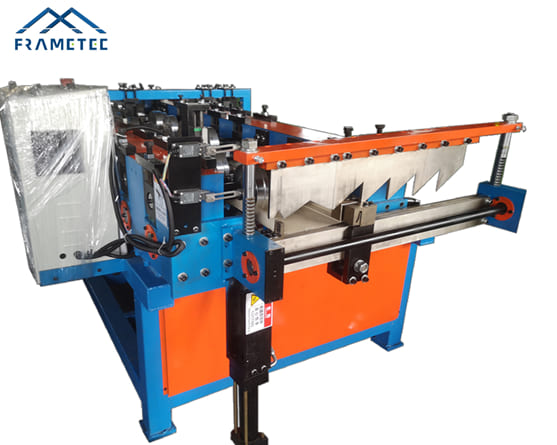

Roll Forming And Transmission Device

One set guiding roller Steel plate welded platform to carry the sheet and feed into roll forming system Feeding width is adjustable with the handle wheels

rollers: material is 45# steel, after CNC precision turning it will go with hard chrome plating, brushed and polished, the surface of the roller finish reaches mirror standard

Gear and 12A chain,this design will make machine more strong, to prolong the machine using life. We make grooves to inset two nuts and cushion on the shaft. To avoid shafts loosing when machine works. Due to this design, shafts will be fixed more and more firm when it is working

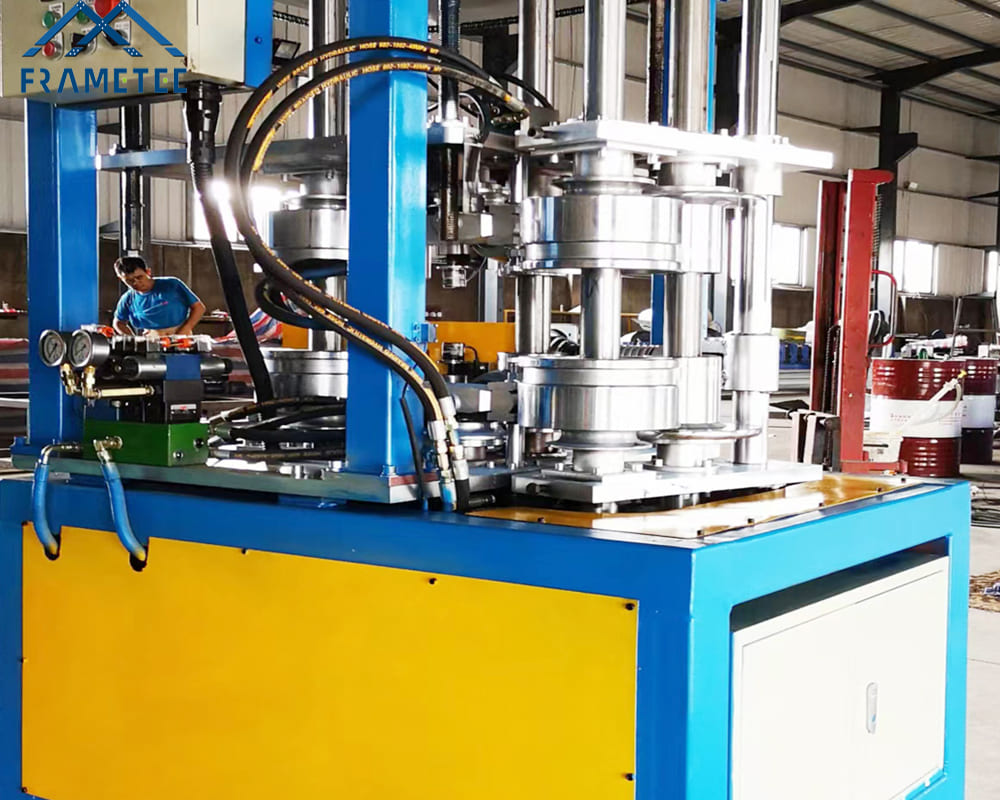

Hydraulic Cutting Device

Work type :Hydraulic cutting Driving method :By pillar type Cylinder Hydraulic motor power :2.2 kw Cutting feature :Steady and safe working condition

PLC control system

PLC Brand: Delta (original), also have buttons on the panel

Screen language: English/Chinese

Cut command :Yes

Profile length set-up :Yes

Batch quantity program :Yes

Low pressure electric part :Schneider brand

Encode :Japan Koyo

Remark :Support multi orders input,ensure the machine can work continuously according to different request without stop ;All the electrical parts are branded with a high quality, it can be fixed easily if damaged.

Hydraulic station

Advantage: with air-cooling system to prolong the service life. Oil tube and wires connection: All wires will be marked by numbers or letters,So very easy to connect. Power:4.5kw

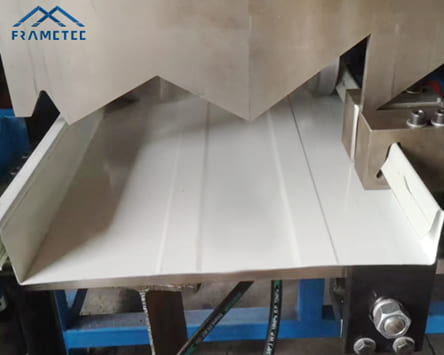

Profile effect:

Assembly tools:

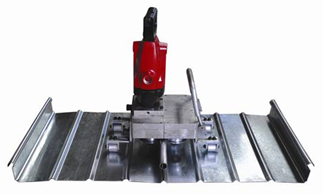

Electric Seaming Machine

Hand Seaming Pincers

Transportation Package

Applilcation:

Our Factory

Why Choose us:

14 years’ manufacturing experience in cold roll forming machine

Competitive price and good quality

One year free warranty

Fast response of after sale service

Can be customized by clients’ requirements

Easy operate and easy to maintain